Categorization:Product Information

The role of automotive wiring harness in the whole car is to transfer or exchange power signals or data signals of the electrical system to realize the functions and requirements of the electrical system. It is the main body of the network of the automobile circuit, and there is no automobile circuit without the wiring harness. Automotive wiring harness design process and manufacturing process is more complex, requiring wiring harness engineers careful and meticulous, can not have a little sloppy. If the wiring harness design is not good, can not be part of the organic combination of functions, it is possible to make the wiring harness to become a faulty automobile links. Below, I briefly talk about the specific process of automotive harness design and manufacturing. First, the first electrical layout engineers to provide the function of the car's electrical system, electrical load and related special requirements. Electrical parts of the state, installation location, harness and electrical parts of the form of docking. Second, according to the electrical layout engineers to provide the electrical function and requirements, you can draw the vehicle electrical schematic diagram and wiring diagram. Third, according to the electrical principle circle for each electrical subsystem and circuit energy distribution, including power supply lap wire, and grounding points. Fourth, according to the distribution of each subsystem electrical parts, to determine the wiring form of the wiring harness, each car wiring harness connected to the electrical parts and the direction of the car; to determine the form of external protection of the wiring harness and the protection of the over-hole; according to the electrical load to determine the fuse or circuit breaker; and then according to the amount of fuses or circuit breakers to determine the wire diameter; according to the function of the electrical parts, based on the relevant standards to determine the wire wire color; according to electrical parts The connector itself to determine the wiring harness with its terminal and sheath type. Fifth, drawing two-dimensional wiring harness diagram and three-dimensional wiring harness layout. Six, according to the approved three-dimensional wiring harness layout, check the two-dimensional wiring harness map, two-dimensional wiring harness map is accurate before sending the map, after approval, according to the wiring harness map trial production, production. The above 6 processes described too general, the specific process of automotive wiring harness design, will encounter many such and such problems, need to be calm and quiet wiring harness designers to analyze, to ensure that the wiring harness design of the rationality and reliability, to ensure the smooth progress of the vehicle circuit design.

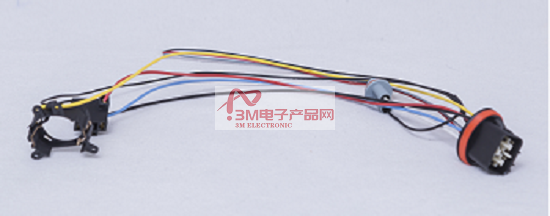

-Seven, on the 3M electronic products network platform related to the introduction and sales of products brief: 3M electronic products network - a professional agent / production / sales of a variety of {connectors | wiring harness | wire and cable products }; if you have a related [connectors | wiring harness | wire and cable products] purchasing / sourcing needs or would like to buy / to understand which connectors | wiring harness | wire and cable products we can provide solutions, please contact the Division I business personnel below; If you have related [connector | wire harness | wire and cable production] sales / resources and promotion needs, please click on the ¡¡ Business Cooperation ← ¡" to discuss with a person!