Categorization:Product Information

Automotive wiring harness is the main body of the network of automotive circuits, the intention is to connect a variety of electrical appliances, its effect is similar to the blood vessels in the human body, is the channel of the current signal. Automotive wiring harness is composed of wires, connectors, terminals, and cards, tape and other auxiliary materials, modern automotive market competition pressure, in order to achieve a win-win effect, wiring harness manufacturers need to ensure that the product meets the customer's quality requirements together with a lower cost to achieve higher efficiency. To control the cost of automotive wiring harness products, first of all, the need to improve the cost of parts analysis of the qualification and accuracy, for the type of automotive wiring harness parts cost a series of analysis and research, using a variety of different analysis methods, from which to select the appropriate control of automotive wiring harness product cost control methods.

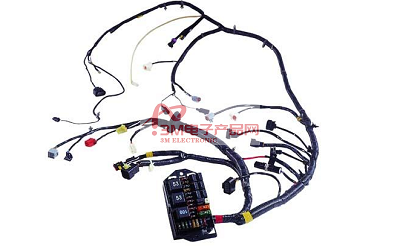

1 on the design of wire harness products harness service object is the load source, it refers to the wire and articulation terminals and other parts assembled together with the wire harness, is the transmission of power and accelerate the transmission of the signal carrier, is the automotive communication hub of the various categories.1.1 types of automotive wiring harnesses and composition of automotive wiring harnesses in accordance with the structure of the different can be divided into the full benefit of the cost of wiring harnesses, some of the benefit of the cost of wiring harnesses and link system; in accordance with the different ways to serve According to the difference of the structure, it can be divided into full profit cost wiring harness, part profit cost wiring harness and link system; according to the difference of the service method, it is divided into lost system wiring harness and waiting system wiring harness; according to the difference of the number of attached sources of service, it is divided into unlimited load quantity wiring harness and limited load source wiring harness. In addition to these, there is a classification, is divided into the main wiring harness and small wiring harness, this statement is based on the number of parts to distinguish between, which, the main wiring harness, including the engine wiring harness, floor wiring harness, instrument panel wiring harness, etc., the small wiring harness, including the roof harness, reversing radar harness, door wiring harness, and so on. The so-called wiring harness, is the use of insulating materials will be a variety of wire bundled into a bundle, will be different colors, different specifications of the wire into one, the more complete and unified, to facilitate its safety. 60% of the actual current-carrying capacity of the wire and 60% to 100% of the actual current-carrying capacity of the wire, respectively, for long-time work and short-time work of the two types of electrical equipment. The cross-sectional area of the selected wires is chosen based on the magnitude of the load current of the automotive electrical equipment. In order to facilitate the recognition of the wires in each wire harness, different colors and letters representing the color are used. Wiring harnesses are generally made up of plastic parts, terminals, wires, line protectors, rubber parts, brackets, fixing parts, and other attachments (including tapes and sleeves) that are installed according to a certain process. If the proportion of raw material costs according to the harness to do Plato, then the wire, plastic parts, terminals, the three types of material costs is the largest part of the proportion. Raw materials for wiring harnesses are mainly purchased parts, to control the cost of raw materials is the primary way to optimize the cost of raw materials for the three parts of the wire, plastic parts, terminals through the standard and VAVE approach. 1.2 Material properties of wiring harnesses and process production of automotive wiring harnesses in various places of the wire requirements are stringent, is also unusual. Mostly from its electrical properties, temperature resistance and material dispersion, etc., than: engine wiring harness wire must use high temperature, oil resistance, resistance to oscillation, conflict resistance; active transmission on the wire is high temperature resistance, resistance to hydraulic oil, good stability; luggage compartment cover on the wiring harness must be selected to maintain its inherent elasticity in a low-temperature environment, and therefore should be selected to ensure that cold elasticity of the wire to ensure that it is itself a normal job ABS wiring harness needs high temperature conditions, generally pick 150-200 ℃ high temperature environment, strong insulation, wear-resistant, but to pick more than 133 stranded wires. The performance of automotive wiring harness products can be divided into two kinds, one is to carry the power to drive the executive element of the power line, the other is to transmit the sensor input command signal line. The thick wire with the effect of transporting large current is the power line, and the thin wire without the effect of transporting electricity is the signal line. Followed by the changing needs of society and science and technology, automotive module performance in the increasing, electronic technology in modern new cars have been commonly used, electronic control system and automotive wiring harness has a close connection. As mentioned in the beginning of this article, the effect of the wiring harness is similar to the blood vessels in the human body, which is an essential element. There is such a metaphor: the ECU and other types of automobile control module is equivalent to the car's brain, all kinds of sensors on the car is equivalent to the sensory neurons, the implementation of components is equivalent to the movement of organs, the wiring harness is the nerves and blood vessels. In the combination of technology and automotive performance, but also produced a lot of confrontation and problems, for example: how to effectively and reasonably placed in the limited space of the car, so that the automotive wiring harness to maximize the effect and performance. Automotive wiring harness process production can be generally divided into four processes: one is the open wire and crimping process, the second is the pre-assembly process, the third is the total assembly process, and ultimately the total assembly of the post-process. Open line process needs to be serious and rigorous, its accuracy affects a whole production progress, presenting a slight error will affect the production power. So now the vast majority of wiring harness factory are using full-active open wire equipment; crimping process needs based on customer crimping specifications and terminal types to recognize crimping parameters and the need for crimping molds. Because the crimping quality is directly related to the electrical performance, so this workstation is a key workstation, the need to have a special characteristics of the crimping operation manual, and in accordance with the prescribed process by the proportion of online sampling to check the quality of crimping to form the characteristics of the control chart; on the pre-installation process, the primary task is to open the line in accordance with the instructions to crimp a good wire in and out of the plastic parts made of KIT, which helps to cut down on the assembly line equipment capital costs, reduce the difficulty of assembly operations, cut down on the assembly of the assembly line equipment costs, cut down on the difficulty of operation, reduce the cost of the assembly line equipment. This will help to reduce the capital cost of assembly line equipment, reduce the difficulty of assembly operation, and reduce the number of assembly operators. On the simple automotive wiring harness can be directly withdrawn from the pre-installation, and on the complex automotive wiring harness generally have to set up the first pre-installation station; after the assembly process, according to the process description of the pre-installed wiring harness will be placed in an orderly manner in the assembly assembly board, and finished finishing the wiring harness, wrapping around the tape, bundling Cardin, the installation of rubber parts and other accessories. The final is the final assembly process, including the installation of brackets, power test, scale full test and bundling packaging, etc. 2 automotive wiring harness cost control and analysis of wiring harness cost is mainly for the material cost and production cost, the use of accounting and benchmarking method of automotive wiring harness components cost composition analysis and exploration, to obtain the automotive wiring harness components of the measurement of the cost of the method, in order to improve the accuracy of the analysis of the cost of the automotive wiring harness components. Parts and components of the accuracy of cost analysis.2.1 Accounting method in a clear understanding of the product composition of the automotive wiring harness and production process under the premise of the automotive wiring harness through the product parts and product structure of the accounting analysis, as well as the analysis of the cost of each part of the accounting analysis, with the accounting analysis method can be calculated to analyze the cost of various types of elements. Now the automotive wiring harness cost includes: raw material costs, production costs and other costs in three parts. 2.1.1 Material costs based on the harness design requirements, product engineers will be from the perspective of the selection of materials / direction / performance and other aspects of the design of the wiring harness product drawings and recognition of the wiring harness bill of materials. After the product design part of the wire harness bill of materials and purchasing part of the purchase of parts recognized by the unit price, in accordance with the sale of wire harnesses supplied by the proportion of models and models of the annual output of the project can be guessed in accordance with the cost of each set of wire harness materials. This process of product design resolution plan will have a direct impact on the cost of raw materials for the harness. 2.1.2 Production costs through the process of product production analysis, automotive wiring harness production process mainly includes open wire process, crimping process, pre-installation process, assembly and testing. Harness cost and process production process planning has a close relationship, for example, whether the need to set up the pre-assembly work, ultrasonic station in the total assembly or pre-assembly to do, the placement of the box orientation will directly affect the harness production costs. Harness process design is related to the input of equipment, personnel input and the design of the place, the whole process design is centered on one goal, that is, how to improve production power and as far as possible to improve the existing equipment, place, personnel utilization. 2.1.3 Other costs other costs include the cost of handling the first, all kinds of development and support costs to additional transportation costs. In the early stages of the project to do the budget will generally be the cost of raw materials plus production costs and multiplied by the corresponding coefficient as an estimate. Other costs = (raw material costs + production costs) * coefficient of aggregation after accounting for the three types of primary costs that the cost of the harness. Related to the standardization method, the results of the accounting method is relatively accurate, but the time required is longer. 2.2 The standardization method in the product offer stage of many parts of the information is not yet complete, in this case it is necessary to recognize the general price of the parts through the standardization of information. Through the benchmark to find similar base point parts, through the difference between the comparison step by step analysis of the cost of the harness price. According to the detailed degree of information grasped by the standardization method, the degree of accuracy of the different degrees of accuracy of the cost of the price of the standard also has a certain degree of difference, but its advantage is that the guessing speed is faster. If followed by the development of big data era, there are further database analysis as the background, the production of data models will greatly improve the readiness of price guessing.3 Conclusion around the socialist core values, in today's society is facing a fierce market struggle, the rapid development of the economy, expanding the entire automotive industry's vision of development, get the attention of all walks of life in the community and focus. The internal development of the automobile industry will focus on how to both improve the performance of new product development and can cut cost overhead competitiveness. In the process of new product development in the automobile, set up the design concept centered on the economy, reduce the acquisition cost of new products on the market, and maximize the profit of new models, which is of great significance to the market competition of the automobile industry. Because of the constraints of time and the relative backwardness of our country's science and technology level, in addition to the accounting method and benchmarking method that has been discussed in this paper, it should be continued to discuss and explore.

2、About 3M electronic products network platform related to the introduction and sales of products briefly: 3M electronic products network - a professional agent / production / sales of a variety of {connectors | wiring harness | wire and cable products }; if you have a related [connectors | wiring harness | wire and cable products] purchasing / sourcing needs or would like to buy / to understand which connectors | wiring harness | wire and cable products we can provide solutions, please contact our business staff below; if you have a related [connectors | wiring harness | wire and cable products] sales / resources and promotion needs, please click "→ Business Cooperation ← with a dedicated person to discuss! If you have related [connector | wire harness | wire and cable production] sales / resources and promotion needs, please click on the "¡¡ Business Cooperation ←" to discuss with a person!