Categorization:Product Information

With the continuous improvement of modern automobile requirements for safety, comfort and environmental protection, the number of circuits and power consumption on the car increases significantly, so how to more effectively and reasonably lay out a large number of wiring harnesses in the limited space of the car has become a problem faced by the automobile manufacturing industry. This paper focuses on the layout of automotive wiring harnesses and briefly introduces the considerations in the layout of automotive wiring harnesses.

I. First, the wiring harness fixing points are reasonably arranged and reliably fixed (1) according to the actual installation position of the wiring harness on the whole vehicle. In order to avoid sagging and displacement of the wiring harness, taking into account the weight of the wiring harness, the fixing method and the convenience of the fixing position, it is necessary to fix the wiring harness with sufficient and reasonable fixing points and fixing methods. (2) According to the direction of the wiring harness and the specific shape of the car body are fixed points, the distance between the two fixed points is generally not more than 300 mm; no support points on the straight line distance; obtuse corner position can be set a fixed point; right angle corner should be set two fixed points, the wiring harness should be avoided in the sharp corner. (3) According to the shape and outer diameter of the wire harness should be selected as the type and size of the fixed buckle to meet the need to bear the weight of the harness. (4) In the position of the connector and other wire harnesses and electrical connections, the fixing point should be set in front of the connector not more than 120 millimeters of the appropriate location. (5) Consider setting a fixing point on the trunk line at the location of the pivot point that is not more than 100 mm away from the pivot point.(6) In the direction of the installation of the fixing buckles, there must be sufficient space to facilitate the installation and removal of the buckles.

Second. Neat appearance and bundle configuration (1) Wiring harnesses should be arranged along the edges and grooves (designed on the body of the vehicle) to avoid direct pressure on the harness. No wiring harness shall be exposed in the cab; set up obvious attraction points or distinctive colors in locations where the harness can be observed, such as the cab. Wiring harnesses installed here are inconspicuous. (2) Arrangement shall be in a horizontal, flat and vertical chevron pattern in the direction of projection to avoid diagonal arrangements. (3) The clearance with the piping is even and the clearance with the surrounding parts is reasonable.

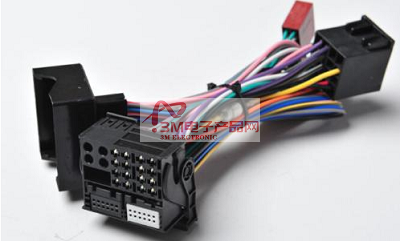

2、About 3M electronic products network platform related to the introduction and sales of products briefly: 3M electronic products network - a professional agent / production / sales of a variety of {connectors | wiring harness | wire and cable products }; if you have a related [connectors | wiring harness | wire and cable products] purchasing / sourcing needs or would like to buy / to understand which connectors | wiring harness | wire and cable products we can provide solutions, please contact our business staff below; if you have a related [connectors | wiring harness | wire and cable products] sales / resources and promotion needs, please click "→ Business Cooperation ← with a dedicated person to discuss! If you have related [connector | wire harness | wire and cable production] sales / resources and promotion needs, please click on the "¡¡ Business Cooperation ←" to discuss with a person!