Categorization:Product Information

Common Problems in Wire Harness Processing: Our own factory staff will encounter various small problems when doing in-line beam processing. We ourselves have observed the following points, some operators on the production line know that the common problems in the processing of wire harnesses are more common. Problems and solutions: 1. When wearing the plastic case, is the terminal PIN When the plastic case is worn, the terminal wire will be removed from the PIN. How do we solve it? In fact, inserting one hole at a time requires only a pull back action and a small hole. All operations can help us to avoid this problem.2. Wires tinnedWires once tinned, the PVC may shrink. In this case, you have to choose high temperature resistant PVC. some wires don't need high brain temperature. The control of tin does not last long. It mainly depends on your own judgment experience.3. Insufficient tensionIf the tension of the harness is not reached, you can choose the following reasons to find the cause: whether the crimping range of the terminals and wires is appropriate; blade materials and their structural design; terminal materials, etc.. We need to know clearly in advance.4. Stickers do not stick If the label does not stick, we do not directly contact the adhesive surface when using stickers, so as not to lose the adhesion of the label. First stick it on a clean metal, stick it in the corner, take it down, and then one goes. Stick to it.

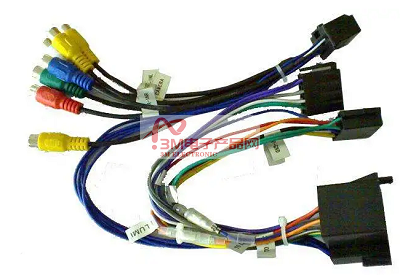

Processing of engine wiring harnesses is a technical activity, which is characterized by many problems during assembly and fitting. Timely detection and study of treatment programs is the principle. Precautions in the assembly process of wiring harness processing: in the assembly process, automotive wiring harness processing needs to follow certain principles. To this end, the harness manufacturer has collated a few points to note when assembling the harness: 1. When assembling, do not pull the harness too tight, so as not to cause displacement of the harness fixing point due to bumps when the vehicle is moving, resulting in an increase in the distance between the two fixing points, and the harness becomes longer, resulting in the internal contacts of the harness false connection or pulling off the wire, wire parameter changes, and in severe cases, even break the wire. 2. After the harness is assembled, there should be enough clearance around it in order to pass through, to ensure that it will not be pressed by other parts, tripped by parts, to avoid wear, breakage or pinching of the harness insulation, which may cause grounding and other faults.3. Do not place connectors of the same color and type in close proximity to each other, so as to avoid incorrectly inserting and damaging electrical appliances and harnesses when assembling them.4. The connectors should be placed in a place where they are easy to locate and easy to manipulate with tools and hands. This is mainly to facilitate inspection and maintenance. The length of the wires should be considered according to the actual assembly. If the electrical device is installed in a place where it is easy to operate, it can be omitted and the plug connector can be directly connected to the component. If the installation location of the electrical components is hidden, it will be difficult to inspect and maintain them later. Depending on the specific needs, the length of the wires of the electrical device can be increased appropriately so that the connector can be installed in a place where it is easy to inspect and maintain.

2、About 3M electronic products network platform related to the introduction and sales of products briefly: 3M electronic products network - a professional agent / production / sales of a variety of {connectors | wiring harness | wire and cable products }; if you have a related [connectors | wiring harness | wire and cable products] purchasing / sourcing needs or would like to buy / to understand which connectors | wiring harness | wire and cable products we can provide solutions, please contact our business staff below; if you have a related [connectors | wiring harness | wire and cable products] sales / resources and promotion needs, please click "→ Business Cooperation ← with a dedicated person to discuss! If you have related [connector | wire harness | wire and cable production] sales / resources and promotion needs, please click on the "¡¡ Business Cooperation ←" to discuss with a person!