Categorization:Product Information

The main problems that are likely to occur in the production process of the row of pins and nuts are missing pins, the flatness is not qualified, the holding force is not enough, the plastic does not resist high temperature. Missing pins row of pins row of motherboard, in the production process due to raw materials or assembly reasons, often lead to missing pins, which is fatal bad, can not be allowed. How to ensure that defective products do not flow into the client, is the factory must be treated strictly, although each product must be fully inspected, but rely on the eyes of the staff to see, it is inevitable to see more will be fatigued. At present, Huicheng Yuan has added the automatic detection of missing pin device on all the machines to ensure that the missing pin products are screened out at the first time and enter the defective products box.

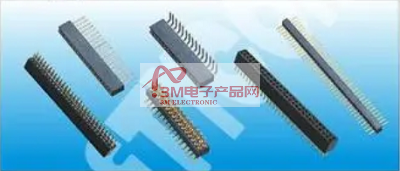

Flatness failure with the rising cost of labor, more and more companies choose to use SMT connectors, tape and reel packaging, automatic placement, in order to improve production efficiency and reduce labor costs. Select SMT products, the most afraid of flatness problems, once the flatness is bad, the product will be weak welding, not conduction, to the quality of a great hidden danger, and return to repair, make-up welding, is also very cumbersome. How to control the flatness, to ensure that the product one-time pass rate of 99.9%, has become the top priority of the enterprise quality control. Suzhou Huicheng Yuan Electronic Technology Co., Ltd. for the control of flatness has the following effective hand breaks: 1. for the amount of small, did not realize the automated machine detection of the product, do control fixtures, flatness adjusted to 8-10S, when the product is smooth through the fixtures into the tube, then the flatness of the qualified, when the product is stuck or not smooth, then the flatness of the requirements have not been met, put into the box of defective products to be inspected, repair. 2. for the inability to realize the automated machine detection and not through the fixtures, but also to ensure that the product one-time pass rate of 99.9%, it will become the most important business control quality. For the products which can not be detected by automatic machine and do not pass the fixture, use CCD to detect the flatness to make sure the flatness of each product is OK. 3. For the large quantity of rows of pins and needles, equipped with CCD device on the automatic machine, after detecting the flatness, automatically enter the tape packaging link. 4. Insufficient holding forceHolding force is an easy to ignore in the row of pins and nuts, but often cause major quality accidents. For example, the row mother of rubber core and terminal between the holding force is not enough, in the welding PCB is not easy to find in, once welding is completed, and row pins inserted, the holding force is not enough will lead to the row of pins in the pull out, will be the row mother of the rubber core as a whole out, leaving only the row mother of the terminals on the PCB board. This batch of bad, will bring great trouble to the company. Shuo Ling's row of pins row mother rubber core and terminals, including four pins, are produced by the company, so at the beginning of the mold design, has completed a good match, just so, far from being enough. Shuoling in the material control is quite strict, when a batch of terminals or rubber core production out, will first carry out the actual match, test the holding force, insertion and extraction force is in the standard range of class, qualified before warehousing into production. Sent to the production line assembly, respectively, in the first piece, inspection, finished product sampling three links to keep the force and insertion and extraction force test, while making a good record. Plastic is not high temperature at present, the row of pins and nuts, commonly used plastic materials are, PBT, PA6T, PA9T, LCP several kinds. PBT is only suitable for wave soldering PA6T, PA9T, LCP three can be over the wave soldering, but also over the reflow soldering patch products must be over the reflow soldering, must be purchased high temperature material, so in the customer inquiries, we must understand the customer's processing technology. But even with high temperature resistant material, there will be rubber core over the furnace deformation, blistering problem, this is why, PA6T, PA9T and LCP material, in the production out of the storage in the warehouse, two or three months do not use, will be due to the material's water absorption, resulting in over the furnace blistering deformation. So Shuoling company documents clearly stipulate that all plastic materials, in the warehouse storage for one to three months unused, and then use, must be tested by reflow soldering, whether it will be deformed, blistering, qualified before the normal issue of material production. If the stock 3 months, not only to test, but also need to re-bake, can send material production.

2、About 3M electronic products network platform related to the introduction and sales of products briefly: 3M electronic products network - a professional agent / production / sales of a variety of {connectors | wiring harness | wire and cable products }; if you have a related [connectors | wiring harness | wire and cable products] purchasing / sourcing needs or would like to buy / to understand which connectors | wiring harness | wire and cable products we can provide solutions, please contact the Division I business personnel below; If you have related [connectors | wire harness | wire and cable products] sales / resources and promotion needs, please click on the "¡¡ Business Cooperation ←" with the person to discuss!