Categorization:Product Information

Insulation resistance refers to the voltage applied to the insulating part of the connector, which causes leakage currents within or on the surface of the insulating part and presents the resistance value. It is mainly affected by insulation material, temperature, humidity, dirt and other factors. Connector samples provided on the insulation resistance value is generally in the standard atmospheric conditions of the index value, in some environmental conditions, the insulation resistance value will not have a degree of decline.

A safety parameter insulation resistance refers to the voltage applied to the insulating part of the connector, so that the insulating part of the surface or the surface of the leakage current and the resistance value. It is mainly affected by insulation materials, temperature, humidity, dirt and other factors. Connector samples provided on the insulation resistance value is generally in the standard atmospheric conditions of the index value, in some environmental conditions, the insulation resistance value will not have a degree of decline. In addition, we should pay attention to the insulation resistance of the test voltage value. According to the insulation resistance (MΩ) = voltage added to the insulator (V) / leakage current (μA) to apply different voltages, there is no need for the results. In the connector test, the applied voltage is generally 10V, 100V, 500V three grades. Second, the withstand voltage withstand voltage is the contact between the mutual insulating part or insulating part and ground, in the specified time can withstand than the rated voltage is higher than the critical voltage does not produce breakdown phenomenon. It is mainly affected by the contact distance and creepage distance and geometry, insulator materials and environmental temperature and humidity, atmospheric pressure. Third, combustibility of any connector in the work are inseparable from the current, there is a risk of fire. Therefore, the connector is not only required to prevent ignition, but also required in the event of ignition and fire, can be self-extinguishing in a short period of time. In the selection should pay attention to the choice of flame-retardant, self-extinguishing insulating materials, electrical connectors. Fourth, the mechanical parameters of single-leg separation force and the total separation force connector contact pressure is an important indicator, which directly affects the size of the contact resistance and contact on the amount of wear. In most structures, direct measurement of contact pressure is quite difficult. Therefore, the contact pressure is often measured indirectly by the separation force of a single pin. For round pinhole contact pairs, usually with a specified weight weight of the standard pin to test the ability of the negative contact piece clamping weights, generally the diameter of its standard pin is the lower limit of the diameter of the positive contact piece to take -5 μm. the total separation force is generally a single foot separation force on the line and twice the sum. Total separation force of more than 50N, with manual insertion and removal has been quite difficult. Of course, for some test equipment or some special requirements of the occasion, you can choose zero insertion and extraction force connector, automatic disconnect connector and so on. Fifth, the environmental parameters of the environmental parameters are mainly ambient temperature, humidity, temperature change, atmospheric pressure and corrosive environments. Connector in the use and storage, transportation process in the environment on its performance has a significant impact, so it must be based on the actual environmental conditions of the selection of the corresponding connector. Sixth, the ambient temperature of the connector metal materials and insulating materials determine the connector's operating temperature. High temperatures will destroy the edge of the material, resulting in insulation resistance and voltage performance reduction; for metals, high temperatures can make contact with the loss of elasticity, accelerated oxidation and deterioration of the plating. The usual ambient temperature of -55 ~ 100 ℃ special occasions may require more. Seven, humidity relative humidity greater than 80%, is the cause of electrical breakdown to cause. Humid environment caused by water vapor absorption and diffusion on the surface of the insulator, easy to reduce the insulation resistance to the MΩ level below, long-term in a high humidity environment, will cause physical deformation, decomposition, escape generation, respiratory effects and electrolysis, corrosion and cracking. Especially in the equipment outside the connector, often to consider the humidity, water seepage and pollution of the environmental conditions, in this case should be used to seal the connector. For watertight, dust-tight connectors are generally used GB4208 shell protection level to indicate. Eight, the rapid change in temperature and humidity test is a simulation of the use of connector equipment in the cold environment into the warm environment of the actual use of the situation, or simulate the spacecraft, detector of rapid changes in ambient temperature. Rapid temperature change may make the insulation material cracks or layer. Nine, atmospheric pressure in the thin air at high altitude, plastic release gas contamination of the contact pair, and corona tendency to increase, voltage resistance decreased, so that the circuit produces a short-circuit failure. At high altitude to reach a certain value, plastic performance deterioration. Therefore, when using non-sealed connectors at high altitude, it is necessary to derate them. Recommended voltage derating coefficients under low pressure, see Table 2. ten, corrosive environments according to the connector of different corrosive environments, the selection of the corresponding metal, plastic, plating structure of the connector, such as the use of the connector in the salt spray environment, if there is no corrosion-resistant metal surfaces, it will lead to rapid deterioration of the performance. In the environment containing a considerable concentration of SO2, it is inappropriate to use silver-plated contact pairs of connectors. Mold is also an important problem in hot and humid areas.

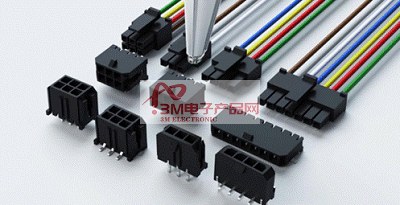

2、About 3M electronic products network platform related to the introduction and sales of products briefly: 3M electronic products network - a professional agent / production / sales of a variety of {connectors | wiring harness | wire and cable products}; if you have a related [connectors | wiring harness | wire and cable products] purchasing / sourcing needs or would like to buy / to understand which connectors | wiring harness | wire and cable products we can provide solutions, please contact the Division I business personnel below; If you have related [connectors | harness | wire and cable products] sales / resources and promotion needs, please click on the ¡¡ Business Cooperation ← ¡" to discuss with a person!