Categorization:Product Information

Traditional connectors have met automotive connector applications by improving many of their designs. However, as new technologies evolve, safer, smarter and greener vehicles are brought to market. As a result, a new generation of connectors is needed to provide connections to these systems. Automotive designers and manufacturers rely on many connector systems that have been popular for decades. Traditional connectors are often used even in modern cars, light trucks and motorcycles. The fact that the tooling and assembly equipment associated with these connector systems is less expensive is great for the economy. However, times are changing. Today, consumers are hungry for safer, smarter vehicles and green energy technologies, and significant advances are being made in automotive technology. These developments often make it necessary for designers and OEMs to find new interconnect solutions.

Key drivers for vehicle propulsion system development should consider the following: * Conventional internal combustion locomotives equipped with 12/14V harnesses. * Light duty hybrids with additional 48-60V battery systems. * Plug-in hybrids and full electric vehicles require additional electrical and electronic systems. Connectors are needed between the motor, inverter and charging mechanism. In addition, the increased use of electronics in vehicles, especially cars and light trucks, means more electrical connections are needed than ever before. Even low-end vehicles now have 30-50 electronic control units (ECUs), while luxury vehicles can have as many as 150 ECUs. at the same time, some vehicles can have as many as 65 central processing units (CPUs), which requires connector technology to reach another level. At the same time, electrical design must also consider clearance and leakage when high-voltage interconnect systems come into play. Since connectors for high-voltage applications typically operate at voltages greater than 12V, this can create another design issue. Additionally, all connections must usually be within a limited space, which can also present space layout challenges. BASIC STANDARDS Making decisions in the electronics world usually starts with standards. The connector industry is no different. The connector manufacturer's expertise, experience and industry history are usually evaluated first. As technologies such as brake and steering cables become more commonplace, a long and lasting reputation is critical for connector systems where reliability is more important than not. Connector suppliers serving the automotive and light truck markets must also comply with global OEM-specific standards as well as industry group standards such as USCAR/EWCAP in the U.S. and VDA in Germany. Four key characteristics to consider when selecting a connector system for a modern vehicle: 1. Size and power handling: As higher levels of functionality are integrated into vehicles, the number of interconnected devices increases, and power requirements increase. However, design space remains largely unchanged or constrained. Miniaturization has been a major trend in this industry for several years, and compact connectors are one of the solutions. Therefore, when looking at interconnect systems, it is necessary to find the best combination of compact size and power handling for the application.

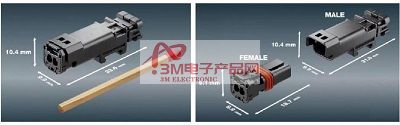

JAE's MX80 series offers the perfect combination of miniaturization and power handling for compact, high-voltage applications, featuring a matched package size of 33.6mmx10.4mm and a maximum current performance of 10A. 2. Performance and specifications: Choosing a more compact connector has often meant a loss of functionality. But this is changing. Today, connector suppliers offer a growing range of miniature connector systems that meet performance requirements such as temperature, vibration and sealing. Interconnects can also feature secondary locking, clip keeper functionality, latching protection and other options, among others. In short, don't compromise on connector performance and specifications unless you absolutely have to. With major suppliers regularly introducing new miniature, high-current connector series, the choices are growing.3. Wide range of wire sizes: The entire vehicle system requires a connector system with a much wider range of wires. Even with different current requirements, the connectors can remain unchanged; only the wire size needs to change. The ability to reuse a single connector system can simplify and speed up the design, manufacturing and inventory management. The range of wire sizes can support waterproof rating (IP) standards to a greater extent, which is particularly valuable.

4. Flexibility: Flexibility in connector systems equates to greater versatility, as well as more opportunities for innovation and improvements that enhance the electrical design and overall vehicle experience. Ultimately, the more flexibility a connector system provides, especially a miniature connector system, the greater the opportunity to save space, weight, time and potentially capital.

Versatility is key when choosing the right solution. JAE's MX80 series is available in both wire-to-interface (shown above) and wire-to-wire connections. Examples of flexibility include connector position assurance (CPA) features, polarization and color coding options, and PC B connector and cable connection options. Connector suppliers often have potential programs to increase the flexibility and versatility of their connector systems. For example, expanding pin counts and adding higher withstand temperatures can enable designers to optimize systems as technology evolves.

JAE's MX80 Series offers three key code polarization options for increased flexibility. Many companies are now enhancing next-generation connector systems that serve modern applications and evolving technologies. It is important to research new connectors and innovate the design. With the same rigor and reliability that will meet the diverse needs of the vehicle industry in the future.

2、About 3M electronic products network platform related to the introduction and sales of products briefly: 3M electronic products network - a professional agent / production / sales of a variety of {connectors | wiring harness | wire and cable products}; if you have a related [connectors | wiring harness | wire and cable products] purchasing / sourcing needs or would like to buy / to understand which connectors | wiring harness | wire and cable products we can provide solutions, please contact the Division I business personnel below; If you have related [connectors | harness | wire and cable products] sales / resources and promotion needs, please click on the ¡¡ Business Cooperation ← ¡" to discuss with a person!