Categorization:Product Information

Although every connector has a rated life cycle, for those connectors that are used in industrial machinery and equipment, incorrect design and some other factors can also lead to premature connector failure, which can result in damage to expensive machinery and equipment. So it's worth paying attention to some of the factors that cause connectors to fail!

1. Connector wear level problem Repeated connection and disconnection of the connector causes the metal on the contacts to wear and corrode when exposed to water, dust, dirt, and other irritating elements, so that the mating pins may not engage properly when inserted into the connector shell. 2. Improper connector selection problem Selection of a connector product that is not of the proper size or specification not only reduces the efficiency of its use, but also shortens the connector's 3. Connector application temperature problems If the connector is not rated for very high or very low temperatures, they will also fail because the connector is not suitable for high temperatures, then the insulation fails and the conductivity will peak. If operated at sustained high temperatures, these spikes will increase in temperature and may cause corrosion and reduce contact force. This can affect the electrical signals traveling through connectors and cable assemblies. While cold temperatures will not affect connectors as severely as high temperatures, low temperature designs should be considered if the application requires it. Applying a connector at a consistently low temperature, as is the case, can cause the tinned connector material to soften, which can increase contact resistance. In addition, low temperatures can affect other parts of the connector, such as making the plastic shell brittle.4. Improper connector design and installation problems If the application of the connector will be encountered shock, vibration and other destructive factors, those who can produce a strong locking of the security design is very important. If not securely mounted, connector contacts, mating shells and even cables may suffer damage. Also, connectors and cable assemblies must be properly strain-relieved and wired for installation, and the use of guide grooves, cable holders, and cable seals can help ensure rated connector assembly life.

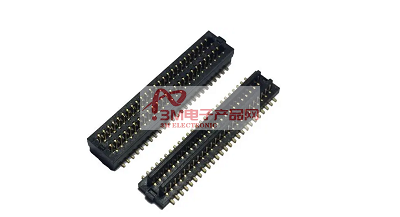

2、About 3M electronic products network platform related to the introduction and sales of products briefly: 3M electronic products network - a professional agent / production / sales of a variety of {connectors | wiring harness | wire and cable products}; if you have a related [connectors | wiring harness | wire and cable products] purchasing / sourcing needs or would like to buy / to understand which connectors | wiring harness | wire and cable products we can provide solutions, please contact the Division I business personnel below; If you have related [connectors | harness | wire and cable products] sales / resources and promotion needs, please click on the ¡¡ Business Cooperation ← ¡" to discuss with a person!