Categorization:Product Information

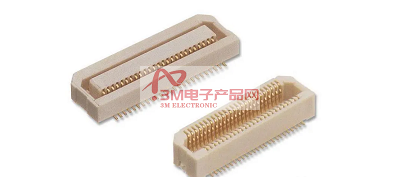

The use of board-to-board connectors has simplified the board design process for smaller PCBs, which of course require manufacturing equipment that may not be able to accommodate larger PCBs.Whether squeezing components or products onto a single PCB or multiple PCBs, there are considerations of power consumption, undesired signal inter-coupling, and the availability of smaller components as well as the overall cost of the finished device or product. In addition to this, board-to-board connectors are also used in a wide range of applications. In addition to this, the use of board-to-board connectors can also simplify the production and testing of electronic devices. In electronics manufacturing, high-density PCBs have more traces and components per unit area. Depending on the investment in complexity of the manufacturing plant, the device or product is best designed with several interconnected MDF boards rather than a single high density board.

Board-to-board connector through-hole technology allows a third dimension to connect traces and components on the PCB. The first PCB can use conductive copper traces along the PCB in both the horizontal and vertical directions. By adding more layers to the board, there will almost always be several single-layer PCBs between the sides of a double-sided PCB. a typical multi-layer PCB with five layers can be less than 0.08 inches (2mm) thick. Through-holes have conductive inner surfaces that can carry current between any two layers of a multilayer PCB. Modern electronic devices are more reliable and cheaper to manufacture due to a variety of proven technologies. PCB manufacturing of multilayer boards used to be a huge challenge due to hidden connections between two or more layers of copper traces. Surface mount technology (SMT) facilitates miniaturization efforts because components can be easily mounted on PCBs even without drilling holes. In SMT, robotic equipment applies adhesive to the underside of the component before adhering it to the PCB. The leads on the pre-tinned leads of the component and the leads on the pre-tinned pads on the PCB are reflowed or remelted, and the soldering process is completed when the PCB cools.

2、About 3M electronic products network platform related to the introduction and sales of products briefly: 3M electronic products network - a professional agent / production / sales of a variety of {connectors | wiring harness | wire and cable products }; if you have a related [connectors | wiring harness | wire and cable products] purchasing / sourcing needs or would like to buy / to understand which connectors | wiring harness | wire and cable products we can provide solutions, please contact the Division I business personnel below; If you have related [connectors | wire harness | wire and cable products] sales / resources and promotion needs, please click on the "¡¡ Business Cooperation ←" with the person to discuss!