Categorization:Product Information

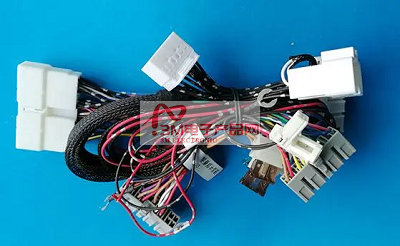

Automotive Handle Door Wiring Harness - Wuling Hongguang_Wire Processing Plant How to prevent oxidation of the wire after the tin electronic wire, insulation test can not be passed? Chenan cable to provide the following tips: flux selection of suitable containers, open the lid after the use of the lid must be twisted to prevent air leakage, air leakage will accelerate the deterioration of the product, thus causing the phenomenon of not on the tin, fried tin. Car Handle Door Wiring Harness - Wuling Hongguang When we choose the wire harness, we need to choose the circuit according to your circuit. If you choose a low voltage harness, choose the wire thickness according to its heating condition, then test the voltage loss and strength. If it is a high-voltage harness, the wire is selected according to its current condition, and the second one is measured for its heat and voltage loss. Each process of wiring harness processing is very important when it comes to wiring harnesses, mainly because the thoroughness of the process enables you to directly relate to the processing of the wiring harness to a certain extent.

When transferring flux it is recommended to use a special pipette to prevent product deterioration. Reuse is not recommended. Automotive wiring harnesses are functionally divided into two types: power wires, which carry electricity to drive the actuator, and signal wires, which transmit input commands from sensors. The power line is a thick wire that carries high current, while the signal line is a thin wire (optical fiber communication) that does not carry power. The cross-sectional area of the wires used for motors and actuators is 0.85 and 1.25mm2, while the cross-sectional area of the wires used for power circuits is 2, 3, and 5mm2; and the last step of the special circuits (starter motors and alternators) is the assembly process. Automotive Handle Door Wiring Harness - Wuling Hongguang 3, may be the aging of the insulator: the aging of the insulator cracked thus leading to the wiring harness can not be properly energized, because in the process of prolonged use, it will lead to poor heat dissipation of the insulator or overload, and thus be destroyed. Then in order to consider the safety of timely replacement of the harness. 4, was damaged: in the process of using the terminal line due to improper operation, damage to the harness, resulting in excessive bending of the harness or any other symptoms. Can be programmed according to the product development department to design the platen assembly, design tooling equipment, materials, box size and accessories jacket and all accessories number affixed to the material to improve the efficiency of the assembly box. Preparation and content requirements for each station assembly, balancing a little bit of work throughout the assembly station to prevent over pulling down the whole line speed situation. Automobile Handle Door Wiring Harness-Wuling Hongguang_Wire Processing Factory Cut the wire to check whether the size of the wire is in accordance with the relevant requirements. Car hand pull door wiring harness-Wuling Hongguang conventional working temperature is 250 ℃, but the actual working temperature can be higher, because the melting point of magnesium oxide is 2852 ℃, much higher than the melting point of copper (1083 ℃), the cable can still be repeated after the fire safety use. This cable production is magnesium oxide stereotypes porcelain column through the copper conductor outside, copper conductor and jacket copper tube at the same time pulling annealed and formed, magnesium oxide porcelain column by crushing uniform formation of the cable insulation, mineral insulated fire prevention cable production length is subject to certain limitations, and the large specifications are even shorter. The model number is not correct. The incision must be neat, can not scratch the wire, and the wire can not have a dirty situation 2, grouping processing check trimming is not neat, the size is right, in the trimming of the grouping can not be scratched to the core wire. 3, peeling the outer skin to check the peeling mouth is not neat, peeling the right size, can not be peeled. Electronic wire manufacturers of power cord monofilament annealing copper, aluminum monofilament heated to a certain temperature, in order to recrystallize the method to improve the toughness of the monofilament, reduce the strength of the monofilament, in order to meet the wire and cable on the conductive core requirements. Annealing process is the key to eradicate the oxidation of copper wire. Electronic wire manufacturers of power line conductor stranded, in order to improve the flexibility of the electronic wire manufacturers of power lines, in order to facilitate the laying device, the conductive core accepts more than one monofilament stranded.

2、About 3M electronic products network platform related to the introduction and sales of products briefly: 3M electronic products network - a professional agent / production / sales of a variety of {connectors | wiring harness | wire and cable products }; if you have a related [connectors | wiring harness | wire and cable products] purchasing / sourcing needs or would like to buy / to understand which connectors | wiring harness | wire and cable products we can provide solutions, please contact the Division I business personnel below; If you have related [connectors | wire harness | wire and cable products] sales / resources and promotion needs, please click on the "¡¡ Business Cooperation ←" with the person to discuss!