Categorization:Product Information

Wire harness terminal crimping standards is an important part of the entire wiring harness process, this time for the wire harness terminal crimping standards mainly from the terminal crimping size and appearance requirements and insertion and extraction force test to explain two aspects. First, crimp size and appearance requirements: 1, test stripping length, wire length, core wire stripping damage. 2. test the length of the residual material 3. conductor crimp area test ① crimp height, width and crimp shape, the back side of the phi not more than 0.13mm; ② pulling force requirements; ③ conductor crimp area must be completely closed and contains all the core; ④ after the trumpet must be visible; ⑤ conductor end must be flush, extend the Crimping area. 4. insulation skin crimping area ① crimp size and shape, no special requirements under the crimping height depends on the size of the wire, in order to be able to crimp the wire skin does not puncture as a standard; ② swing test: hand off the head of the wire 6, 7cm, up and down the bending of 90 °, no loosening indicates that it has been tightly crimped, and then check that the wire skin is acceptable without puncture; ③ in addition to crimp area of the outside of the wire skin is not damaged. 5. shrapnel and terminal with the area of the damage-free Deformation.

Second, the terminal compression insertion and extraction force test test tool: intelligent tensile testing machine test method: 1, take the UL standard or equivalent to this standard wire length of about 50 cm, one end of the terminal according to the test is correctly dissected line. 2, the terminal and the wire with the correct tools and methods of crimping firmly, will be part of the terminal is fixed in the fixed seat end of the tensile machine, the end of the wire is fixed to the fixed seat end of the tensile machine, the end of the cable fixed to the Tensile machine activities seat. 3, start the intelligent tensile testing machine, until the terminals and wires off until. 4, will measure the data and UL standard comparison to determine whether the test is successful. 5, three consecutive tests, all successful to pass Huicheng Yuan as a professional industrial wiring harness processing company, with a very standardized processing technology and strict quality standards. Starting from the details of each industrial wire harness processing, from each harness people professional technology to ensure that the quality of each cable perfect, these are Huicheng yuan from 0 to 1 to establish the standard. If you have any questions about our products, please feel free to contact us.

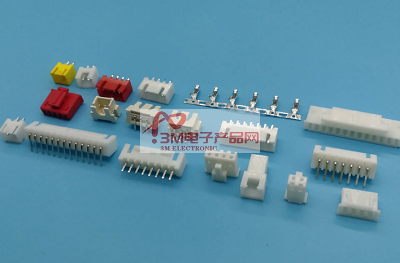

2、About 3M electronic products network platform related to the introduction and sales of products briefly: 3M electronic products network - a professional agent / production / sales of a variety of {connectors | wiring harness | wire and cable products}; if you have a related [connectors | wiring harness | wire and cable products] purchasing / sourcing needs or would like to buy / to understand which connectors | wiring harness | wire and cable products we can provide solutions, please contact the Division I business personnel below; If you have related [connectors | harness | wire and cable products] sales / resources and promotion needs, please click on the ¡¡ Business Cooperation ← ¡" to discuss with a person!