Categorization:Product Information

With the transformation of traditional manufacturing to high-end manufacturing, the wave of "re-industrialization" oriented to intelligent manufacturing is intensifying, and the interconnection and remote interaction of industrial control equipment has become the key to improve the level of automation. Industrial systems include a variety of electrical components and equipment from PCBs, sensors, drives, motors, industrial computers, electrical cabinets, etc. These devices must be connected to each other. All of these devices must be connected to each other and work together, creating a huge demand for industrial control connectors.

According to BishopAssociate statistics, the global mayor/market size of industrial control connectors in 2020 is about $7.722 billion, with a CAGR of about 4.03% from 2010 to 2020. In the United States, Germany and other major industrial developed countries to speed up the process of industrial automation, intelligent development, some developing countries are actively involved in the global industrial redistribution, acquisition of industrial and capital transfers, the use of latecomer advantages to rapidly achieve scale expansion. This is all a direct benefit of the growth in demand for industrial control connectors market. Compared with other types of connectors, industrial control connectors can be widely used in industrial production, especially in the demanding and complex environment of the connection requirements, which is the connector of the mechanical, electrical and environmental requirements of a higher level of comprehensive performance. (1) environmental adaptability based on the complexity of the working environment of the connector in the field of industrial control (for example, dust, dirt, temperature, humidity, mechanical vibration impact, and all other factors may interfere with conventional connections). Therefore, the connector shell, structure, the main contact materials, coating materials and thickness, etc. must be considered in the design of environmental adaptability. (e.g. sealing levels must meet IP67, IP68 standards, and product life and corrosion must meet international EIA standards for industrial applications.) . This connector supplier must strengthen the customization of the design, with the richness of the downstream application scenarios, the reliability requirements of the connector will be further improved. (2) narrow spacing, integration With the improvement of the accuracy of electronic equipment and a variety of electronic systems control capabilities and complexity of the increase, connector products must maintain stability while realizing the narrow spacing and high integration. For example, industrial control equipment, general-purpose board-to-board connectors from the past 2.54 mm, 2.0 mm, 1.27 mm gradually transitioned to 0.8 mm, 0.635 mm and 0.3 mm spacing, wire-to-board I / O connectors also appeared in the development trend of a fairly narrow spacing, the size of the latest mini-I / O connector than the standard I / O connector smaller. At the same time, in the case of multiplexing and other signal parallel transmission technology is widely used, the integration of electrical signals, microwave signals, optical signals, etc. into the same connector, the independent transmission of each signal, without interfering with each other more and more signals. This makes connector integration an inevitable trend. For example, the number of pins corresponding to a single connector is increasing, signal transmission channels are richer, and multiple functions can be performed. In addition, connector suppliers must strengthen the precision machining capabilities and fine-tune the work in the mold, soldering and other process stages to ensure that a narrow gap to achieve a higher level of integration. (3) high-speed, high-frequency Currently, the mainstream transmission rate of industrial control connectors in the 3Gbps or more, and gradually evolve to more than 40Gbps. The greater bandwidth required for data transmission will increase the upper limit of the signal frequency. Connectors are prone to electromagnetic interference in faster speeds and frequencies of signal transmission, so connector suppliers must use electromagnetic simulation software to evaluate the product design aspects, and in the processing and manufacturing to achieve a higher standard of accuracy.

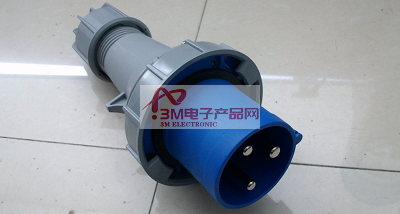

2、About 3M electronic products network platform related to the introduction and sales of products briefly: 3M electronic products network - a professional agent / production / sales of a variety of {connectors | wiring harness | wire and cable products}; if you have a related [connectors | wiring harness | wire and cable products] purchasing / sourcing needs or would like to buy / to understand which connectors | wiring harness | wire and cable products we can provide solutions, please contact the Division I business personnel below; If you have related [connectors | harness | wire and cable products] sales / resources and promotion needs, please click on the ¡¡ Business Cooperation ← ¡" to discuss with a person!