Categorization:Product Information

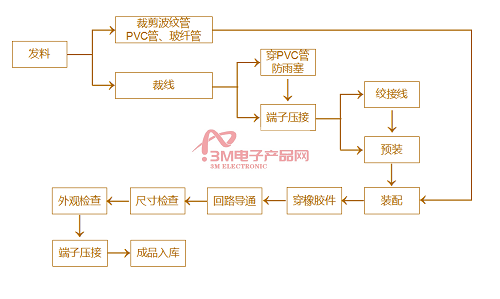

Usually, the manufacturing of automotive wiring harnesses is divided into cut wire crimping, crimping (welding), pre-assembly, general assembly, inspection, packaging processes. The automation degree of the front project's cut wire crimping and wire crimping (welding) process is relatively high, and the automation degree of the back project's pre-assembly, total assembly, inspection and packaging process is low, basically relying on manual centralized assembly, which is a typical discrete manufacturing, and at the same time, it is also a labor-intensive type of manufacturing. A complete set of automotive wiring harness consists of nearly 1,000 materials, assembly is complex and difficult, will inevitably cause assembly errors, resulting in rework and repair, affecting product quality and production efficiency, therefore, the automotive wiring harness product error-proof design and process manufacturing error-proof design is particularly important.

Error-proofing technology is any device or facility that prevents human error from occurring, or that allows errors to be detected at a glance. Error-proofing is also known as the foolproof method and the anti-dumbing method; it means to prevent process errors before they occur. It is a method that employs automatic action, alarms, marking, classification, and other means in the work process so that workers will not make mistakes without paying special attention. In the manufacturing process, a reasonable and effective process error prevention, tooling error prevention can significantly improve production efficiency, reduce the generation of defective products to ensure product quality. With the rapid development of automotive technology, automotive electronic and electrical parts, the increasing number of functional parts, connecting the electrical parts of the wiring harness is also more and more complex, the number of circuits and the volume of the wiring harness is also growing rapidly; and consequently the wiring harness process design, manufacturing, process inspection and quality control have brought about great difficulties. Inevitably lead to a variety of human manufacturing errors in the various processes of harness manufacturing, resulting in semi-finished or finished harnesses batch rework rework, a serious impact on the wiring harness manufacturing efficiency and product quality enhancement, resulting in a waste of man-hours and raw materials. So in the wiring harness manufacturing process using error-proof technology, through the process of error-proof design and tooling error-proof design becomes an effective means of avoiding the emergence of wiring harness manufacturing errors.

2, on the 3M electronic products network platform related to the introduction and sales of products brief: 3M electronic products network - professional agent / production / sales of a variety of {connectors | wiring harness | wire and cable products }; if you have a related [connectors | wiring harness | wire and cable products] purchasing / sourcing needs or would like to buy / to understand which connectors | wiring harness | wire and cable products we can provide solutions, please contact the Division I business personnel below; If you have related [connectors | harness | wire and cable products] sales / resources and promotion needs, please click on the ¡¡ Business Cooperation ← ¡" to discuss with a person!