Categorization:Product Information

High-voltage wire harnesses such as the need to pass through the sharp edges or holes should be designed to protect the structure or way, in the early stages for the development of the vehicle when the wire harness layout need to try to avoid the heat source vibration source or else with which to maintain a sufficient distance. High-voltage wire harnesses have a larger diameter and weight, in order to avoid stress concentration, the minimum bending radius of the cable is generally greater than the diameter of the wire diameter of 5 times, to reasonably distribute the load, the need to increase the support fixtures, harness straight line arrangement of fixed-point spacing ≤ 300mm, over the curved arrangement of fixed-point fixed in the arc at the end of the two points, fixed-point spacing with the connector ≤ 150mm, to be able to withstand the weight of the wire bundle and vibration load. The fixing device must be automotive grade cable ties and insulation brackets. Drive motor harnesses need to consider the impact of component movement and vibration, the size of the harness should be reasonably designed to meet the length of the distribution of stress, but also to avoid excessive length of the harness caused by the buildup. For the harness movement to increase the rubber ring buffer and guide groove fixing structure, to avoid the harness and other components of the cuts, resulting in damage to the harness. Wire harness layout process to consider EMC electromagnetic interference factors, the use of shielded high-voltage cables to avoid high-frequency noise emission, high and low voltage cables must be arranged separately to avoid mutual interference caused by the harness cross overlap each other. Consider the aesthetics of the wiring harness arrangement, the direction should be consistent with the direction of the dependent parts, to avoid oblique direction, for the hairpin wiring harness as far as possible in the structural components or components of the lower or inner alignment, the bottom of the vehicle exposed high-voltage wiring harnesses should be used to protect the tube, shielding plate for shielding protection. Considering the installation and maintenance, for the same part of the connector in order to prevent misplugging should be selected with different specifications and positioning of the connector, the end of the connector needs to leave a certain amount of margin for insertion and removal. Consider high voltage safety, this high voltage has exceeded the human body safety voltage, the body can not be like a low-voltage system like the hitch way, must be used in a two-track system.

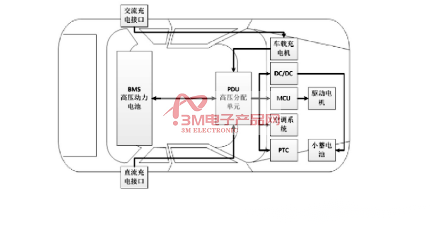

The following figure shows the layout of high-voltage components of pure electric vehicles. The layout of the high-voltage components of the pure electric vehicle is used to rationally arrange the high-voltage connection harnesses between the battery to the PDU, the motor controller to the motor, AC and DC charging and other high-voltage components.

High-voltage connector selection High-voltage connector electrical performance; need to consider the rated operating voltage, rated operating current, insulation resistance, voltage rating, shielding and interlocking and other related electrical performance parameters. Environmental performance; need to consider the operating temperature, ambient temperature, salt spray level, flame retardant level, resistance to solution reagents and banned substances and other requirements. According to different design requirements there will be other requirements. Mechanical performance; according to different working conditions to test the vibration resistance and the corresponding mechanical life. Safety performance; the use of high-voltage interlock, high-voltage interlock is divided into built-in type and external type, due to the built-in type of compact layout and small size, electric vehicles are used in the built-in type, and through the VMS or BMS and other controllers to detect the high-voltage interlock, the requirements of high-voltage connector separation, the charged part can be reduced to 60Vd.c and 30Va.c within 1S below, in order to ensure personal safety. Maintenance switch MSD that is, manual maintenance switch is a key component to ensure the high-voltage electric safety of pure electric vehicles, is capable of realizing the high-voltage system electrical isolation of the execution of the component at the critical moment, can be highly integrated with the breaking device and fuse, in the internal configuration of the appropriate fuse at the same time can also play a circuit overcurrent and short-circuit protection of the protection of the reasonable design and operation of the maintenance switch for the electric vehicle electric safety Reasonable design and operation of the maintenance switch play a vital role in the electrical safety of electric vehicles. The charging interface is currently divided into two types, AC charging interface and DC charging interface, while the AC interface is the AC grid power supply through the cable control and protection devices into the on-board charger. DC interface is the DC power supply equipment with control and guidance function directly connected to the electric vehicle battery. AC interface rated voltage 250Va.c or 440Va.c, rated current current does not exceed 63A, DC interface rated voltage 750Vd.c or 1000Vd.c, rated current does not exceed 250A, according to the requirements of the vehicle layout to determine the rated voltage and current value of the charging interface, AC and DC charging interface and other relevant electrical characteristics of the parameters must meet the national standard GBT20234.2-2015 and GBT20234.3-2015.

2, on the 3M electronic products network platform related to the introduction and sales of products brief: 3M electronic products network - professional agent / production / sales of a variety of {connectors | wiring harness | wire and cable products }; if you have a related [connectors | wiring harness | wire and cable products] purchasing / sourcing needs or would like to buy / to understand which connectors | wiring harness | wire and cable products we can provide solutions, please contact the Division I business personnel below; If you have related [connectors | harness | wire and cable products] sales / resources and promotion needs, please click on the ¡¡ Business Cooperation ← ¡" to discuss with a person!