Categorization:Product Information

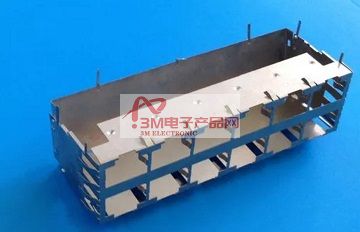

Connector stamping mold is an indispensable tool in the production of connectors, its production quality and accuracy directly affect the quality and performance of connector products. This article will introduce the connector stamping mold production process and considerations. First, the connector stamping mold production process 1. Design mold structure and parameters of the connector stamping mold design should be based on the connector product shape, size and material properties. First need to determine the mold structure and parameters, such as mold shape, mold size, mold material, mold weight, etc. 2. Make mold parts according to the mold structure and parameters, make mold parts. Mold parts include upper mold, lower mold, guide pillar, guide sleeve, pressure plate, spring, etc. 3.Processing mold parts After making mold parts, it needs to be processed. Common processing methods include milling, drilling, milling, grinding, etc. 4. assembly mold will be processed mold parts are assembled to form a complete stamping die. 5. debugging mold assembled mold needs to be debugged. First of all need to carry out no-load test pressure, to determine whether the structure and parameters of the mold is correct. Then the actual production of the test pressure, and constantly adjust the parameters of the mold, until the best production results.6. Maintenance mold mold in the production process will produce wear and fatigue, the need for regular maintenance and repair, in order to maintain the accuracy and life of the mold. Second, the connector stamping die production considerations 1. material selection connector stamping die material should choose high strength, high hardness, high wear resistance alloy steel material to ensure the life and precision of the mold. 2. processing accuracy connector stamping die processing accuracy is very important, directly affects the quality and performance of the connector products. Therefore, when processing mold parts, you need to ensure that the processing precision is high and the dimensions are accurate.3. Mold structural designThe structural design of connector stamping molds should be as simple as possible to facilitate the production and maintenance. At the same time, need to consider the characteristics of the connector products, reasonable design of the mold structure to ensure that the connector product size and shape accuracy.4. Mold debugging connector stamping die in the debugging process need to pay attention to the adjustment of the mold parameters, in order to ensure that the connector product precision and performance. The debugging process should be operated carefully.

About 3M electronic products network platform related to the introduction and sales of products briefly: 3M electronic products network - a professional agent / production / sales of a variety of {connectors | wiring harness | wire and cable products }; if you have a related [connectors | wiring harness | wire and cable products] procurement / purchasing needs or want to buy / to understand which connectors | wiring harness | wire and cable products we can provide solutions, please contact our business staff below; if you have a related [connectors | wiring harness | wire and cable products] sales / resources and promotion needs, please click on the "→ Business Cooperation ←" and discuss with a person! If you have related [connectors | harness | wire and cable products] sales / resources and promotion needs, please click on the ¡¡ Business Cooperation ← ¡" to discuss with a person!