Categorization:Product Information

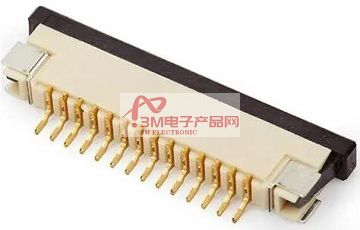

FPC connectors (Flexible Printed Circuit Connector) are bendable circuit board connectors that are commonly used to connect flexible circuit boards (FPC) and rigid circuit boards in electronic devices. They are commonly used in devices such as cell phones, laptops, tablets, digital cameras, etc., and can provide reliability and stability for high-speed data transfer and signal transmission. When packaging FPC connectors, the following considerations need to be taken into account.1. Size and ShapeThe size and shape of FPC connectors are designed according to the application scenarios and the needs of electronic devices. Therefore, when packaging FPC connectors, you need to ensure that their size and shape meet the design requirements. In addition, it is also necessary to consider the FPC connector mounting method and location to ensure that it is compatible with the circuit board.2. Number of pins and arrangementFPC connectors usually have a different number and arrangement of pins to adapt to different application scenarios and electronic devices. When packaging FPC connectors, you need to make sure that the number of pins and the arrangement matches the design requirements to ensure a reliable connection and high-speed data transmission.3. Material SelectionThe selection of materials for FPC connectors has a great impact on their performance and reliability. When packaging FPC connectors, you need to choose the right material to ensure that it has good durability and mechanical strength, and can work properly in different temperatures and humidity conditions.4. Connection method FPC connectors are usually used jack type connection, this connection can provide a reliable connection and can withstand a certain degree of mechanical stress and vibration. When packaging FPC connectors, you need to ensure that the connection is correct to ensure the stability and reliability of the connector.5. Soldering method FPC connectors usually need to be soldered to the circuit board. When packaging FPC connectors, it is necessary to select the appropriate soldering method, such as surface mount (SMT) or through-hole soldering (PTH), to ensure that the connector and the circuit board are reliably connected.6. Environmental requirements FPC connectors are usually used in different environmental conditions, such as temperature, humidity, vibration, etc.. When packaging FPC connectors, you need to ensure that they can work properly under different environmental conditions to ensure the stability and reliability of the connector.

About 3M electronic products network platform related to the introduction and sales of products briefly: 3M electronic products network - a professional agent / production / sales of a variety of {connectors | wiring harness | wire and cable products }; if you have a related [connectors | wiring harness | wire and cable products] procurement / purchasing needs or want to buy / to understand which connectors | wiring harness | wire and cable products we can provide solutions, please contact our business staff below; if you have a related [connectors | wiring harness | wire and cable products] sales / resources and promotion needs, please click on the "→ Business Cooperation ←" and discuss with a person! If you have related [connectors | harness | wire and cable products] sales / resources and promotion needs, please click on the "¡¡ Business Cooperation ←" and specialists to discuss!