Categorization:Product Information

In the electronic and new energy industries, high-temperature resistance has always been a "hard requirement" for connector applications. Fields such as wind power main control, automotive power systems, energy storage equipment, and industrial control often face complex working conditions of high temperature, high humidity, and continuous power supply. Once the connector fails in a high-temperature environment, the safety and stability of the entire system will be greatly compromised.

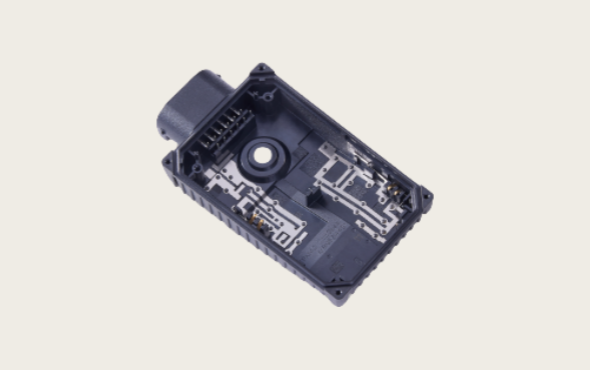

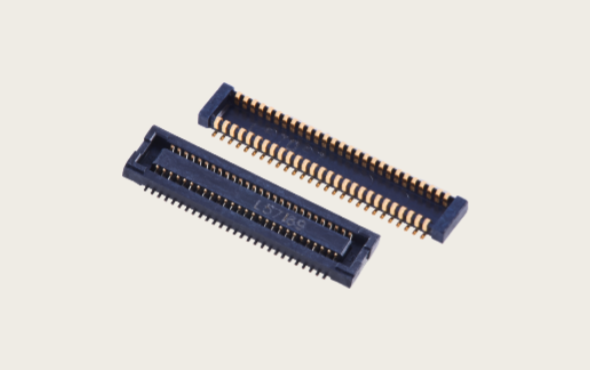

When it comes to the high-temperature performance of connectors, LS Mtron, as a technology company from South Korea and a subsidiary of LS Group, has accumulated many years of research and development in the field of electronic components. Some of its connector products use high-performance engineering plastics, heat-resistant metal contacts, and advanced plating technology. The design working temperature generally covers -30℃ to +85℃, with some models extending to +105℃ even +125℃ to meet the needs of automotive electronics, 5G communication equipment, and new energy applications.

Then, under the same high-temperature resistance test, what is the performance of domestic connectors, "surprise" or "disappointment"?

Core points of high temperature performance testing for domestically produced connectors

Long-term constant temperature aging test

In the high-temperature box, continuous power supply for more than 72 hours is carried out to detect the changes in contact resistance and insulation resistance. In this link, some domestic connectors have already approached the performance of imported brands.

Temperature cycle / thermal shock test

High and low temperatures are repeatedly switched, which poses a challenge to the thermal expansion coefficient matching of plastic and metal parts. After improvement, the domestically produced connector shows a significant reduction in cases of shell cracking and contact loosening in multiple cycles.

3. Contact coating stability

Under high temperatures, the coating of contacting parts is prone to oxidation or peeling. In recent years, domestic manufacturers have improved the coating thickness and adhesion, which has reduced the drift range of contact resistance.

Surprises and deficiencies coexist

Surprise element:

●After material and process upgrades, the stability of domestic connectors at +105℃ has approached the level of imported ones.

●In some new energy and industrial scenarios, the electrical performance remains stable, and the aging resistance performance is commendable.

●Cost and delivery advantages are prominent, providing customers with flexible options.

Insufficient:

In long-term aging tests under extreme high temperatures (+125℃ and above), there are still issues of insulation aging and contact resistance shift.

● Some high-end applications lack large-scale long-term use case validation.

In general, the progress of domestic connectors in high-temperature resistance is evident, from "just passing" to "gradually approaching the import standards," and this has become a reality. With the continuous optimization of materials science and manufacturing technology, the reliability and application scenarios of domestic products are expanding. Although more practical verification is still needed in terms of extreme high temperatures and long-term stability, the trend of domestic substitution is irreversible.

If you are interested in the domestic substitute products for this brand connector or have procurement needs, or if you have production or sales channels for the domestic substitute products of this brand connector and wish to engage in in-depth cooperation or communication, please contact us via the following contact information:Manager Zhang (18665383950, same WeChat number)Contact us, we look forward to joining hands with more industry partners to move forward together.