In many projects, connectors are often regarded as "mature components" or "common components", with relatively little investment. However, it is this unassuming "small part" that may cause major problems on-site or after years of operation if the selection or quality is not up to par: abnormal signals, poor contact, module failure, unstable current, and environmental adaptability collapse... Many customers have had painful experiences with these "failure scenes." Today, let's talk about the things that can go wrong with domestic connectors, and with the capabilities and characteristics of international brand Yamaichi, tell you how to avoid pitfalls and choose the right components.

Yamaichi brand endorsement: technology & product featuresWhen comparing with domestic connector manufacturers, Yamaichi is a good benchmark for reference. From publicly available information, it can be seen that Yamaichi has the following several highlights in the field of connectors/interconnection technology:

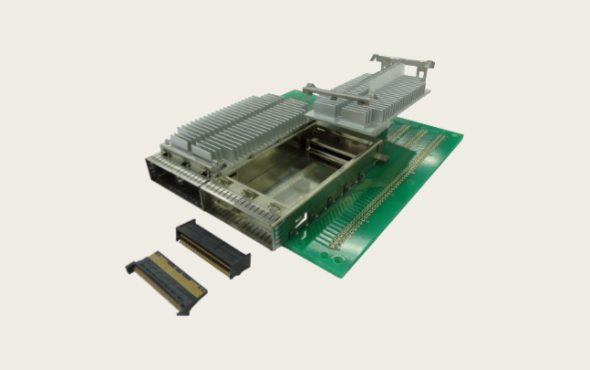

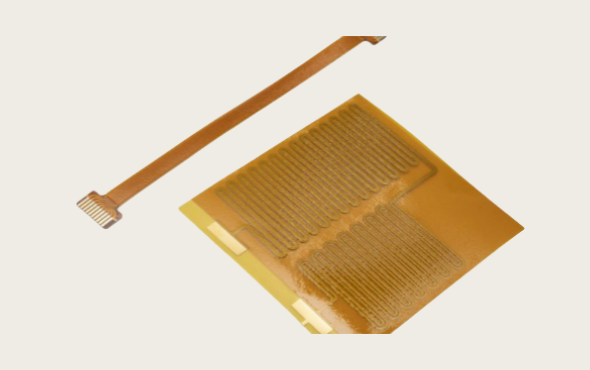

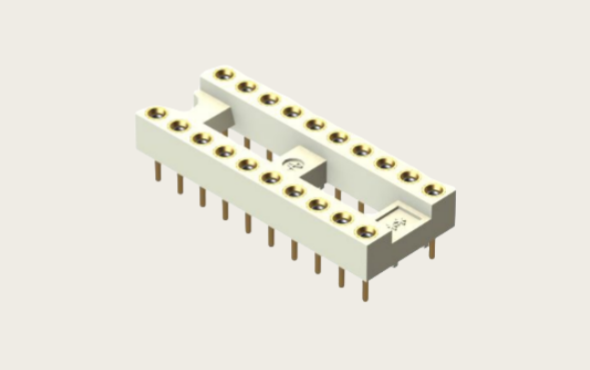

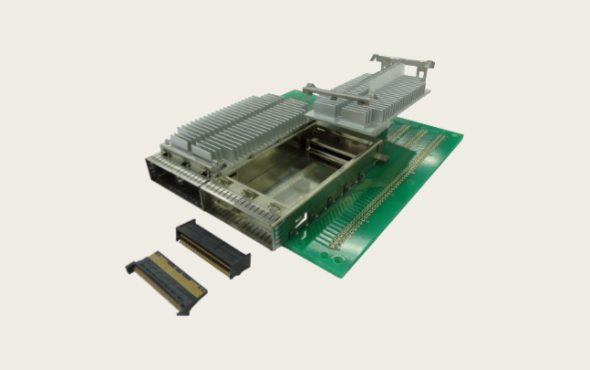

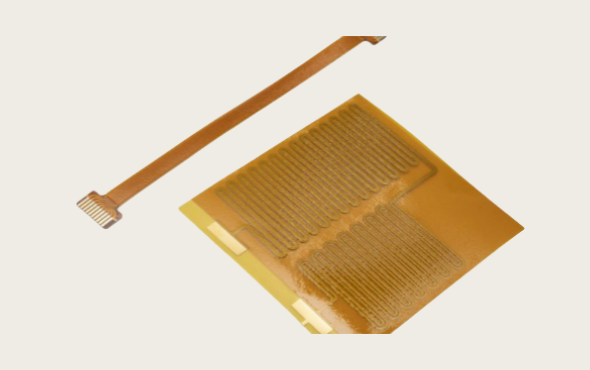

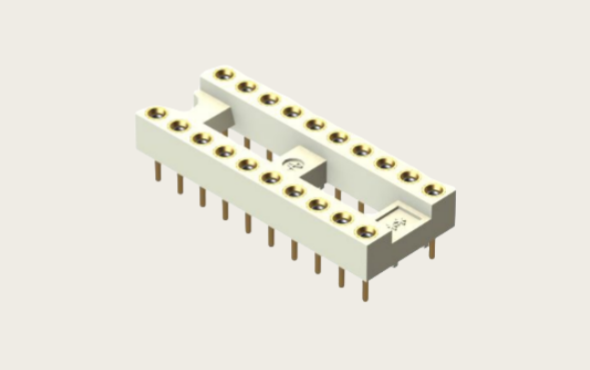

●Rich product line: Yamaichi's Connector business covers high-speed transmission connectors, interface connectors, board-to-board, FPC/FFC, module plug-in connectors, etc.

● High-speed / high-frequency performance: Its high-speed interconnect devices support a variety of high-speed standards and have profound capabilities in signal integrity, matching, and shielding.

●Floating structure design: In the field of board-to-board connectors, floating structure design can tolerate certain alignment deviations.

● High temperature / high current capability: For example, its high temperature Burn-In connector can be used in extreme environments, and the battery connector can support higher current with durability.

● Application reliability and environmental capability: Some connectors can reach a high protection grade, excellent sealing, and anti-vibration capability.

These capabilities combined make Yamaichi frequently used in communication / test / industrial / automotive applications that require high reliability and signal quality. For domestic substitution, in order to match its quality, efforts must be made on those "hard indicators" and "implicit reliability."

Two, real or typical "Chinese-made connector failure scene" typesThe following are several common types of connector failures, which are also easily encountered by many users when selecting or using domestic connectors:

Signal performance突变 / packet loss / error rate

In high-speed links, the internal geometry and electromagnetic matching of domestic connectors are not fine enough, causing abnormal insertion loss, echo, and crosstalk.

●The customer found that the error rate increased and the eye diagram deteriorated after using the system for a period of time.

Poor contact / contact impedance drift

● After long-term use, the needle or contact may oxidize or deform, causing the contact resistance to rise.

●Some connectors exhibit resistance drift even with fewer insertion and removal cycles than the specified specifications.

Environmental adaptability collapse

● Seal failure and accelerated corrosion occur in high temperature, high humidity, and salt fog environments.

Vibration or shock may cause connectors to become loose, disengage, or fatigue and fail.

Thermal Runaway / Insufficient Current

●Serious warming occurs under high current conditions, and poor internal structure design limits heat dissipation.

Stator/busbar design is unreasonable, conductor cross-sectional area is too small, unable to carry continuous current.

Batch consistency poor / Terminal tolerance out of control

Large performance differences exist between different batches, with some batches feeling just right and others being defective.

●Material / process control is not in place, causing dimensional deviation and uneven tightness.

These issues have truly occurred in some customer projects. If you have ever encountered situations like "a module with poor contact, restarting at night, and frequent repairs," then many times the cause may be related to the quality of the connector chosen.

How to avoid these pitfalls as a domestic substitute? Compare with Yamaichi benchmark to see the direction.We provide several suggestion dimensions to help you have a clearer direction when choosing or designing domestic connectors:

Material and contact piece technology should be excellent

High-quality copper alloy, stable coating, corrosion resistance treatment, and contact pressure control must be refined.

The geometric structure and locking mechanism should be reasonable.

There should be a guide, lock buckle, blind insertion or misinsertion prevention mechanism to avoid poor fit due to mechanical deviation.

Electromagnetic / signal design and shielding require precision

In high-speed applications, it is necessary to do well in impedance matching, via design, ground plane layout, and shielding layer design.

Environmental stress testing should be strictly conducted.

Perform high temperature, low temperature, humidity, salt spray, vibration, impact, life acceleration tests, and it is best to provide a complete reliability verification report.

Consistency and quality management system should be sound

Material inspection, process monitoring, sampling testing, aging test, and batch tracking should all have mechanisms.

Early involvement of prototype and field verification is required.

Before system integration, it is necessary to perform end-to-end verification: connector + cable + board joint debugging, to expose potential problems.

If domestic connector manufacturers can do a solid job in the above dimensions, the probability of being "tricked" will be greatly reduced, and the functional stability will be more guaranteed.

Have you ever been deceived by domestic connectors? Indeed, there are many cases, especially in scenarios with high frequency, high speed, and high environmental stress, where defects are more likely to be exposed. However, if you take international brands like Yamaichi as a reference standard and strictly examine domestic connector manufacturers from aspects such as materials, structure, signal, electromagnetic, reliability verification, and quality control system, you can avoid those pitfalls as much as possible. Domestic substitution is not achieved overnight, but through gradually overcoming weaknesses and ultimately establishing trust.

If you are interested in the domestic alternative products of this brand connector or have procurement needs, or if you have production or sales channels for these domestic alternatives and wish to engage in in-depth cooperation or communication, please contact us through the following contact information:

Manager Zhang (18665383950, WeChat number the same)Contact us. We look forward to working with more industry partners to create a more trustworthy future for domestic connectors.