In the field of automotive electronics, connectors as critical electronic components directly affect the stability and safety of the whole vehicle's electrical system. Raydiall Automotive, as a globally leading manufacturer of automotive connectors, its products are widely used in vehicle communication, autonomous driving, intelligent cockpit, and other fields.

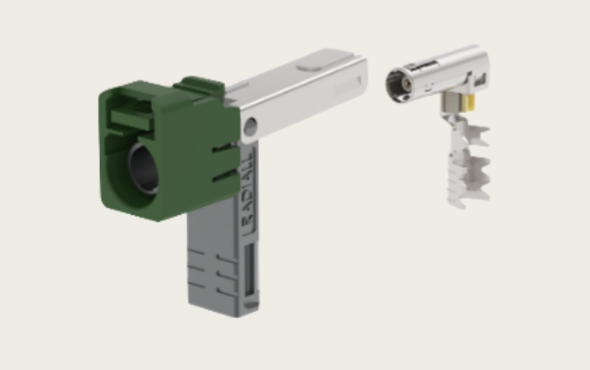

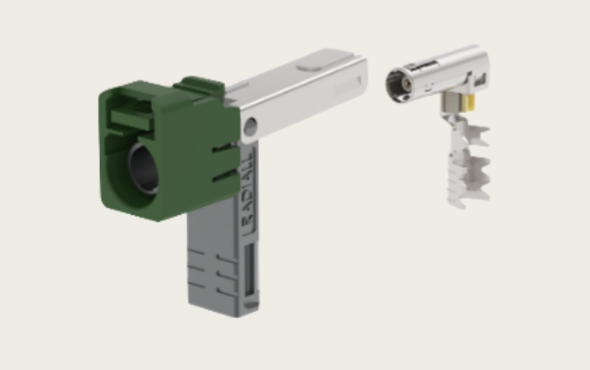

Raydiall's connector products, such as the FAKRA R3C series, use a patented one-step crimping technology that can complete multi-point crimping in a single operation, significantly improving assembly efficiency and reliability.

In addition, its products meet international standards such as ISO 20860 and USCAR-17, ensuring high-frequency performance and mechanical strength.

In the development process of domestic connectors, the scientificity and rigor of the testing process are crucial. The following is the core testing process of domestic connectors:

Mechanical property testing

● Vibration Test: Simulate vibrations generated during vehicle operation to ensure the mechanical stability of the connector during long-term use.

● Insertion/Removal Force Test: Evaluate the mechanical properties of the connector during the insertion/removal process to prevent damage caused by improper insertion/removal.

Environmental adaptability test

●Temperature and humidity cycling test: Simulate the working state of the connector under different temperature and humidity environments, ensuring its reliability under extreme climatic conditions.

Salt spray corrosion test: Test the connector's corrosion resistance in a high salt environment to extend its service life.

Electrical performance test

● Contact Resistance Test: Ensure that the electrical contact of the connector is good under working conditions, to avoid signal loss due to poor contact.

Insulation resistance test: Evaluate the insulation performance of the connector to prevent electrical short-circuit or leakage phenomena.

4. High-frequency performance test

Insertion Loss and Return Loss Test: Evaluate the performance of connectors in high-frequency signal transmission and ensure signal integrity.

●Cross talk and common mode rejection ratio test: Test the interference suppression capability of the connector in multi-channel signal transmission, ensuring stable operation of the system.

Domestic connectors are continuously catching up with the international advanced level in terms of material selection and process design. However, to achieve full benchmarking with international brands like Raydiall, it is still necessary to make continuous efforts in the scientificity, standardization, and automation of the testing process. By establishing a comprehensive testing system, domestic connectors are expected to achieve complementary advantages in performance and cost, meeting the increasingly stringent demands of the automotive industry.

If you are interested in the domestic substitute products for Raydiall brand connectors, or have procurement needs, or possess production or sales channels for these domestic substitute products for Raydiall brand connectors, and wish to engage in in-depth cooperation or communication, please contact via the following contact information:

Manager Zhang (18665383950, WeChat number the same)Contact us, we look forward to working together with more industry partners.