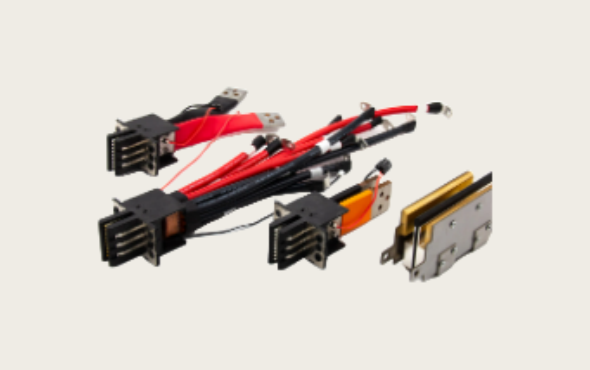

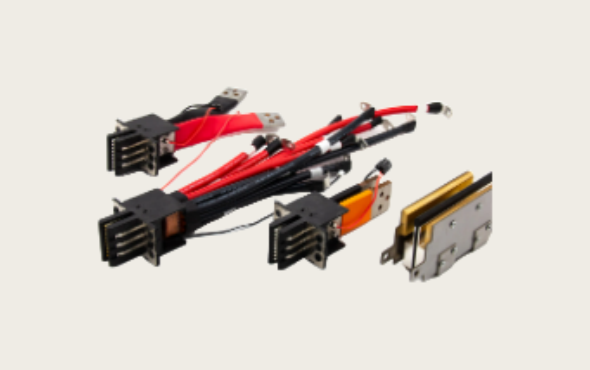

In the increasingly complex context of the global electronics industry, the quality of connectors not only directly affects the stable operation of equipment but also concerns the reliability of the entire supply chain. As one of the globally renowned connector brands, Oupiin has a rich product line, including high-speed backplane connectors, board-to-board connectors, wire-to-board connectors, power connectors, and IDC series, which are widely used in fields such as data centers, 5G communication, new energy vehicles, and industrial automation. With the acceleration of the domestic substitution trend, how to catch up with and exceed international standards in the quality management system has become a core issue that domestic manufacturers must face.

The core link of the quality management systemMaterial quality control

Domestic substitute products have gradually achieved stable supply of high-performance plastics, copper alloys, and environmentally friendly electroplating materials in the raw material stage. Through strict incoming material inspection (IQC), we ensure that each batch of raw materials meets environmental protection requirements such as RoHS and REACH.

Process control in production

Oupiin's original factory production system emphasizes automation and standardization, while domestic substitute manufacturers introduce SPC (Statistical Process Control) and a combined inspection mode of full inspection and random sampling in processes such as stamping, injection molding, coating, and electrical performance testing, in order to reduce defect rates and ensure batch consistency.

Reliability test

Common performance tests include insertion and extraction life testing, high and low temperature cycling tests, salt spray corrosion testing, and electrical strength testing. Domestic manufacturers have gradually established testing processes that align with the same standards as Oupiin, with some products even performing exceptionally well in vibration and high-frequency transmission.

4. Traceability and Improvement Mechanism

Establish a complete batch traceability system (Lot Tracking) and use the 8D report mechanism to close the loop on customer feedback for continuous improvement of the quality management process.

The advantages of the domestic quality systemWith the gradual improvement of the system, domestic substitute products are more flexible in terms of delivery time, cost, and service response. Especially in the case of rapidly growing customized demands from customers, domestic brands can accelerate the introduction and iteration of new products through the method of "small batch trial production + rapid verification."

The improvement of the domestic connector quality management system not only represents the pursuit of international brands like Oupiin, but also signifies a comprehensive enhancement of domestic manufacturers in material control, production processes, and testing standards. As more customers recognize domestic solutions, the process of domestic substitution will be faster and more stable.

If you are interested in the domestic substitute products for this brand connector or have procurement needs, or if you have production or sales channels for the domestic substitute products of this brand connector and wish to engage in in-depth cooperation or communication, please contact via the following contact information:

Manager Zhang (18665383950, same WeChat number)Contact us, we look forward to working together with more industry partners.