Categorization:Product Information

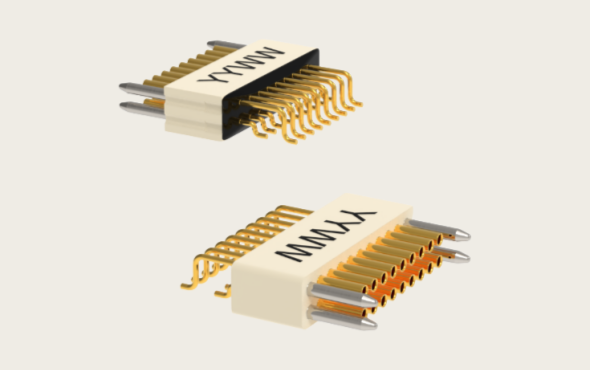

Omnetics, as an internationally renowned manufacturer of miniature connectors, its products are widely used in aerospace, medical equipment, military and communication industries. Its advantages not only lie in the miniaturized design, but also in the high standard selection of materials and strict quality control:

●Alloy pin: Utilizes high-strength gold-plated alloy pins to ensure stable signal transmission and corrosion resistance.

●Shell material: Chosen lightweight metal and high-performance plastic, balancing strength and weight.

●Environmental adaptability: Possesses characteristics such as resistance to high and low temperatures, vibration resistance, moisture resistance, and corrosion resistance, ensuring reliability under extreme conditions.

These materials and process standards also provide an important reference direction for domestic manufacturers.

One, the core points of quality control for domestic connector materials

In the process of domestic substitution, the selection of materials and quality control are the core links. This is mainly reflected in the following aspects:

Conductive material

Domestic manufacturers should choose high-conductivity copper alloys and enhance their corrosion resistance and plug-pull life by gold or nickel plating processes.

Insulating material

Common engineering plastics such as PBT, LCP, and PPS need to meet requirements for heat resistance, moisture resistance, and insulation strength to ensure that they do not deform or age under high-frequency and high-temperature conditions.

Electroplating process

Surface treatment is a key factor affecting the lifespan and performance of connectors. Domestic manufacturers should strictly control the coating thickness and uniformity to ensure the number of insertion and extraction reaches the design requirements.

4. Environmental reliability test

Covering temperature cycles, salt spray tests, vibration and shock tests, etc., to ensure the product can adapt to complex application scenarios such as communication base stations and medical equipment.

5. Standardization and Consistency

Domestic manufacturers need to establish testing and quality control processes in line with international standards (such as MIL, IEC) to ensure consistency of material performance during mass production.

The important significance of quality control to the replacement of domestic products

With the rapid application of domestic connectors in industries such as 5G base stations, industrial control, new energy, and medical electronics, material quality control has become a key factor determining the success of domestic substitution. Only when the material process reaches the standard of international high-end brands can domestic connectors truly break through in terms of performance, reliability, and lifespan, thus gradually narrowing the gap with international brands such as Omnetics.

Omnetics connectors have maintained their competitiveness in the high-end market for a long time, which is closely related to their strict material quality control. For domestic manufacturers, material management, process optimization, and standardized testing will become the inevitable path to promote the in-depth development of domestic substitution.

If you are interested in domestic alternatives to Omnetics brand connectors, or have procurement needs, or possess production and sales channels for domestic alternatives, and wish to engage in in-depth cooperation or communication, please contact:Manager Zhang (18665383950, WeChat number same)We look forward to joining hands with more industry partners and jointly promote the high-quality development of domestic connectors!