ElectronAix provides a variety of high-quality connectors and cable components, suitable for industrial, communication, automotive and other fields. Its product line includes board-to-board (BtB), circular, FFC/FPC and other types of connectors. The "Floating BtB Connector" structural design can significantly reduce wear and corrosion between contact points; some FFC products have passed salt spray testing, with no corrosion or oxidation found in the contact area before and after the test. In addition, ElectronAix's circular and MIL-Spec connectors are manufactured in factories certified by ISO 9001 and AS 9100, emphasizing quality and reliability.

Integrated standard and method for anti-corrosion testing of domestic connectorsCombining the product characteristics of ElectronAix and the anti-corrosion testing specifications, the following key points can be emphasized in the promotional article:

Salt Spray Test

Salt spray test is an important means to evaluate the anti-corrosion performance of connectors. The ElectronAix part FFC connectors have passed a 24-hour salt spray test under the conditions of 35 °C and pH 6.5–7.2, with no corrosion or oxidation occurring in the contact area before and after the test.

This performance can serve as an important quality basis for domestic alternative connectors, demonstrating reliable performance in corrosive environments such as marine and road salt撒.

Microfretting corrosion and structural design resistance

Microcorrosion is caused by vibration or thermal expansion and contraction, which leads to slight contact movement, and is an important test for the durability of connectors. ElectronAix adopts a Floating BtB design, effectively reducing the risk of this type of corrosion.

Emphasize the value of structural innovation in enhancing the durability of domestic connectors during promotion.

3. Industrial Standards and Composite Environment Testing

Although the ElectronAix specifications do not elaborate, common industry test methods include Kesternich tests (SO₂ environment), IEC 6988 flow gas corrosion environment, as well as comprehensive environmental tests such as temperature and humidity cycling, temperature shock, etc.

It is recommended that the domestic ElectronAix connector passes the standard tests in this manner to enhance market trust and quality assurance.

4. Coating and Material Protection Strategies

As indicated by industry articles, applying precious metal coatings such as gold plating or alloy coatings can significantly reduce corrosion. The coating should control the porosity, and using clad gold alloys is better than electroplating in terms of fewer pores, comparable cost, and better protective effect.

ElectronAix adopts gold plating technology in FFC products, such as the FA05 series which uses Au plating layer (≥ 2 µ") and meets environmental regulations such as RoHS / REACH.

Article graphic structure layout suggestions (independent station style)● Title Area (Visual Attraction): Highlight the keywords "Corrosion Resistance Performance," "Testing Standards," and "Domestic Connectors."

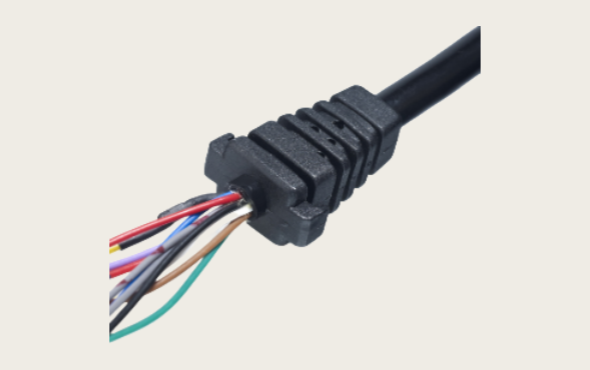

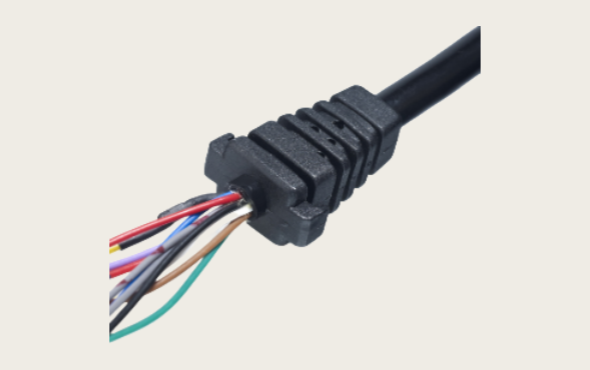

● Product display/image/structure diagram: ElectronAix Floating BtB structure diagram, FFC connector coating detail image, or test machine photo can be inserted (suggested to have backup images).

● Core Content Block

Product Introduction and Design Features

Standard test methods and results (salt spray, micro-motion corrosion, comprehensive environmental testing)

Material coating technology and effect explanation

● Emphasis on comparison: Add a graphic and textual comparison of the anti-corrosion performance of the domestic ElectronAix connector with other domestic or imported products.

Emphasize selling points such as "Through rigorous testing," "reliability improvement," and "accelerating the replacement of domestic products."

The domestic ElectronAix connector has demonstrated excellent stability in micro-motion corrosion and environmental corrosion tests through rigorous salt spray testing, remarkable structural design, and high-quality plating technology. With the compound environment durability test in accordance with industry standards, it can further enhance the product's reputation and service life in the domestic market. Regardless of high-demand environments such as industry, communication, or automotive, this domestic connector can achieve excellent corrosion resistance and provide customers with long-term reliable connection assurance.

If you are interested in the corrosion resistance and test data of ElectronAix brand connectors made in China, or have procurement needs for such products, or if you have production or sales channels for ElectronAix domestic connectors and wish to engage in in-depth cooperation, please feel free to contact us through the following contact information:

Manager Zhang (18665383950, WeChat number the same)Looking forward to working with more industry partners to promote the development of domestic anti-corrosion connectors.