Under the continuous pursuit of equipment safety, reliability, and precision in the medical industry, the performance stability of connectors, as one of the core components, is particularly crucial. For a long time, international brands such as Amphenol Positronic have occupied the high-end medical equipment connector market with their technical accumulation and product stability. However, with the progress of domestic technology and the gradual implementation of application cases, domestic connectors are gradually opening up application space in medical equipment and becoming a key breakthrough for the new round of domestic replacement.

One, the role of Amphenol Positronic connectors in medical devicesAmphenol Positronic is a globally renowned manufacturer of high-performance connectors, skilled in providing solutions for harsh environments. Its products are widely used in medical terminal equipment such as MRI imaging devices, patient monitors, surgical systems, and high-energy laser therapy devices. Its advantages lie in:

●Excellent EMI/RFI shielding performance, suitable for medical environments where signal interference is extremely sensitive.

● Modular design for easy maintenance and system integration;

●High-precision contact terminal design ensures long-term connection reliability.

A comprehensive global certification system that meets the requirements of different market access.

But under the background of tight international supply chain and rising cost pressures, issues such as high prices and long delivery times have become an important consideration for medical device manufacturers.

Second, the application practice and case analysis of domestic connectorsWith the improvement of domestic manufacturers' technological level, several domestic connector brands have achieved structural compatibility and performance equivalence with some models of Amphenol Positronic, and have successfully realized application deployment in the medical industry. The following is a typical application case:

★ Project Background

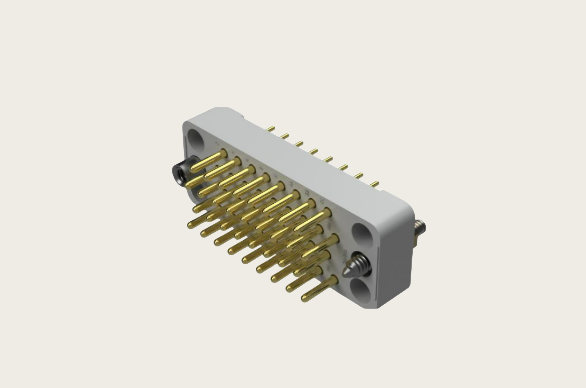

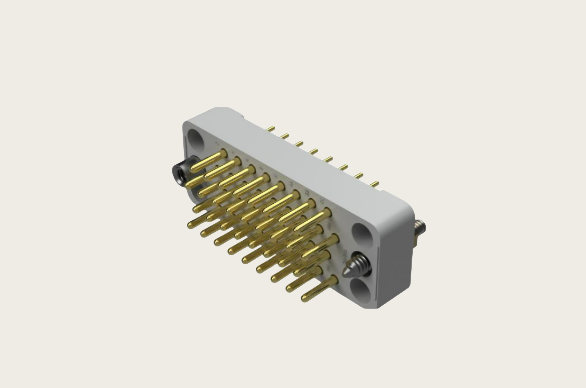

A domestic medical device company encountered two problems during the trial production stage of its new generation of visual endoscopy equipment, where the original plan was to use Amphenol Positronic's high-density D-Sub connector.

●The original factory delivery time requires more than 8 weeks, affecting the product launch rhythm.

The cost is too high, which is not conducive to controlling the overall selling price of the mid-to-low-end product line.

★ Alternative Solution Implementation

After assessment, select a certain country's brand for customized compatibility development:

Interface size and pin arrangement are fully compatible and can be directly replaced.

● The shell material is changed to domestic aluminum alloy die-casting, with anti-interference shielding layer;

●Electrical performance tests pass high-frequency signal stability and anti-interference tests.

★ Project achievements

The final product has achieved stable application of domestic connectors, with cost reduction of about 30%, delivery period shortened to within 12 days, customer feedback is good, and it is now in mass installation.

Why is the medical industry increasingly accepting domestic connectors?Cost advantage: Domestic connectors can significantly reduce the connection cost per unit of equipment without compromising safety and functional performance.

Technical support flexibility: domestic brands respond quickly, support customized interface layout, EMI structural design, etc.

●Certification Continues to Improve: More and more domestic manufacturers have passed relevant medical device compatibility certifications such as ISO13485, RoHS, and REACH.

●Stable localization supply chain: Especially in the domestic market, domestic brands have fast delivery and easy after-sales service, which is a powerful guarantee for supply chain stability.

Although the high-end medical equipment connector market is still dominated by international brands, domestically produced connectors are gradually making breakthroughs in the mid-range and emerging medical equipment fields. Especially in the realistic scenarios of tight equipment development cycles, high delivery requirements, and cost control, the replacement of domestic products is no longer a temporary measure, but a practical choice and trend.

If you are interested in the domestic substitute products for this brand connector or have procurement needs, or if you have production or sales channels for these domestic substitute products and wish to engage in in-depth cooperation or communication, please contact us through the following contact information:

Manager Zhang (18665383950, WeChat same number)Contact us, we look forward to working together with more industry partners.