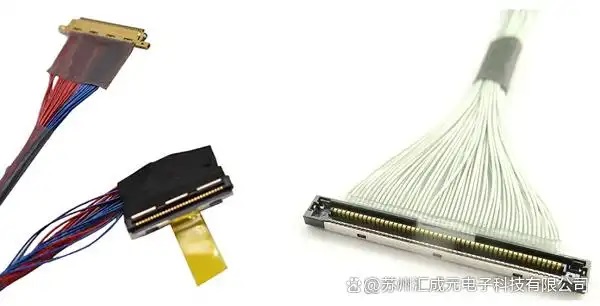

As electronic devices continue to develop towards thinness and high speed, Micro Coaxial Cable has been widely used in applications such as laptops, tablets, camera modules, medical equipment, and other scenarios with extremely high requirements for signal integrity and anti-interference performance. However, the processing difficulty of ultra-thin coaxial cable bundles is extremely high, and any carelessness may cause signal loss or structural damage.

The three major technical challenges of ultra-fine coaxial beam processing

Extremely thin wire diameter, extremely small operating space

Taking the commonly used AWG#40 specification as an example, its conductor diameter is only 0.09mm, and the overall outer diameter is only 0.37mm. Traditional welding methods are prone to wire core breakage or insulation layer damage, with extremely small process tolerances, making it difficult to ensure the yield of finished products.

Welding precision is extremely high

The inner part of the extremely thin coaxial cable consists of an inner conductor, an insulating layer, a shielding layer, and a sheath layer. During welding, it is necessary to ensure that the structure of each layer is intact and undamaged. The weld joint must be clean and firm, while avoiding affecting the signal transmission performance.

It is difficult to control the consistency of high-frequency signals

Due to the fact that ultra-fine coaxial cables mainly undertake high-speed data transmission tasks, any minor processing defects can cause signal attenuation, reflection, or crosstalk, thereby affecting the overall system performance.

HTK LVC-D30LPMSG+ : Mini coaxial cable connector for specialized applications

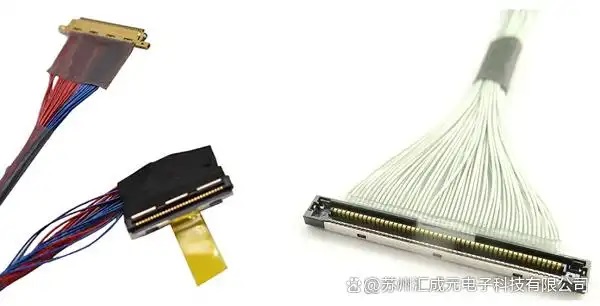

In response to the above challenges, HTK (Honno Denshi) has launched the LVC-D30LPMSG+ connector, which is specially designed for ultra-thin coaxial cable bundles. This series has been optimized in terms of structure, performance, and process compatibility, making it an ideal choice for high-density signal transmission systems such as laptops and LCD monitors.

Product highlights include:

0.5mm ultra-fine pitch design — suitable for high-density board line connection.

Support high-speed data transmission —— Optimize structural design, significantly reduce signal propagation skew.

Low-back structure - saves PCB installation space, improves overall system integration.

Pulse-Heat pulse heating welding technology —— Avoids thermal damage to the wire core and insulation layer, significantly improves welding stability and consistency.

Section 3: Electrical Performance Parameters

Rated Voltage: 50V AC

Rated current: 0.3A/Pin

Insulation resistance: ≥100MΩ (250V DC)

Voltage resistance: 150V AC / 1 minute

The processing of extremely fine coaxial cable bundles is a highly technical process that requires high precision of equipment, process capability, and experience level. The HTK LVC-D30LPMSG+ connector, with its professional design and pulse welding technology, not only effectively solves the core problems of difficult to weld extremely fine conductors and poor signal consistency, but also provides a more stable and reliable connection solution for high-frequency and high-speed applications. Choosing a service provider with mature processing technology for extremely fine coaxial cable bundles is crucial for ensuring the integrity of high-speed signals and the long-term reliability of products.

I am Kunshan JieKangFu Precision Electronics, focusing on the design and customization of high-speed signal cables and ultra-fine coaxial cables for a long time, committed to providing stable and reliable high-speed interconnection solutions to customers. If you have related needs or want to learn more, please contact: Manager Zhang.

18913228573 (WeChat number).