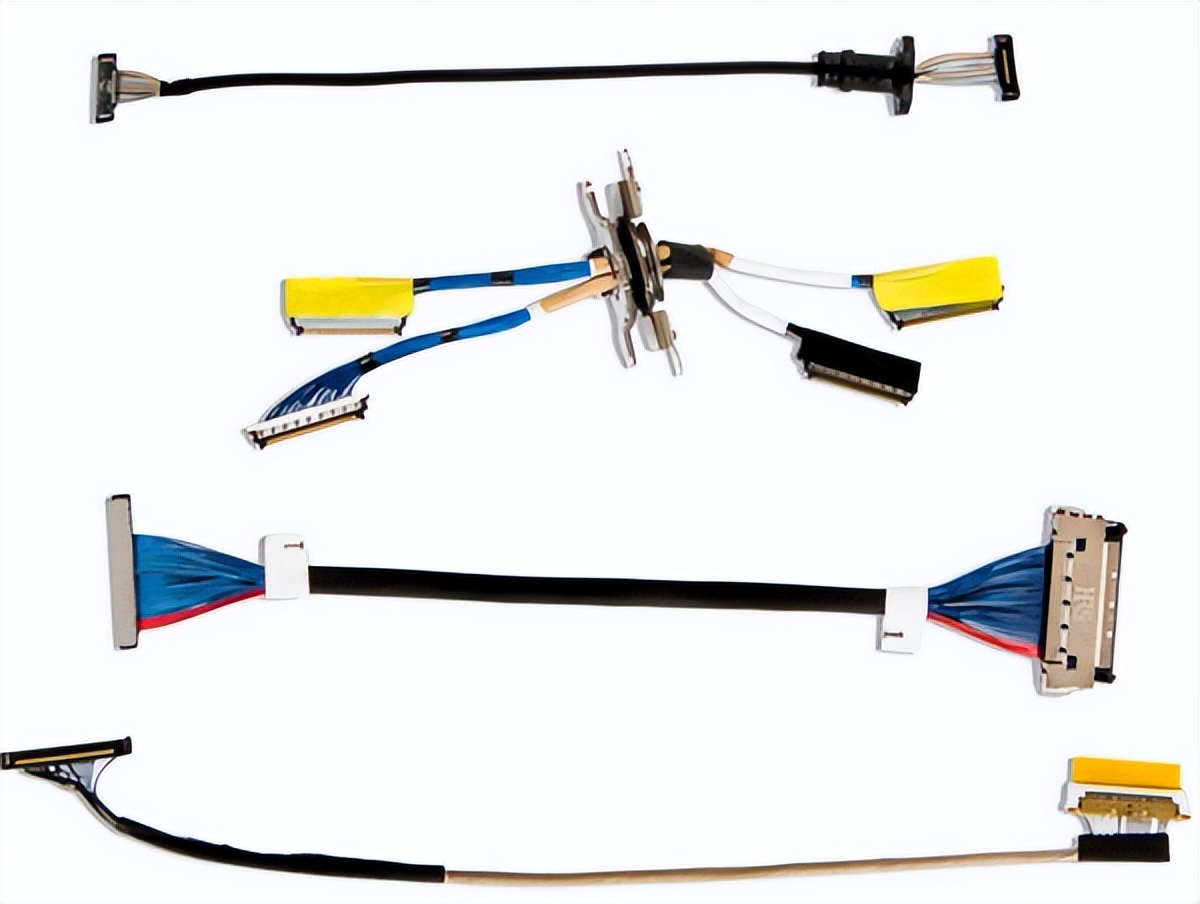

Categorization:Harness Component

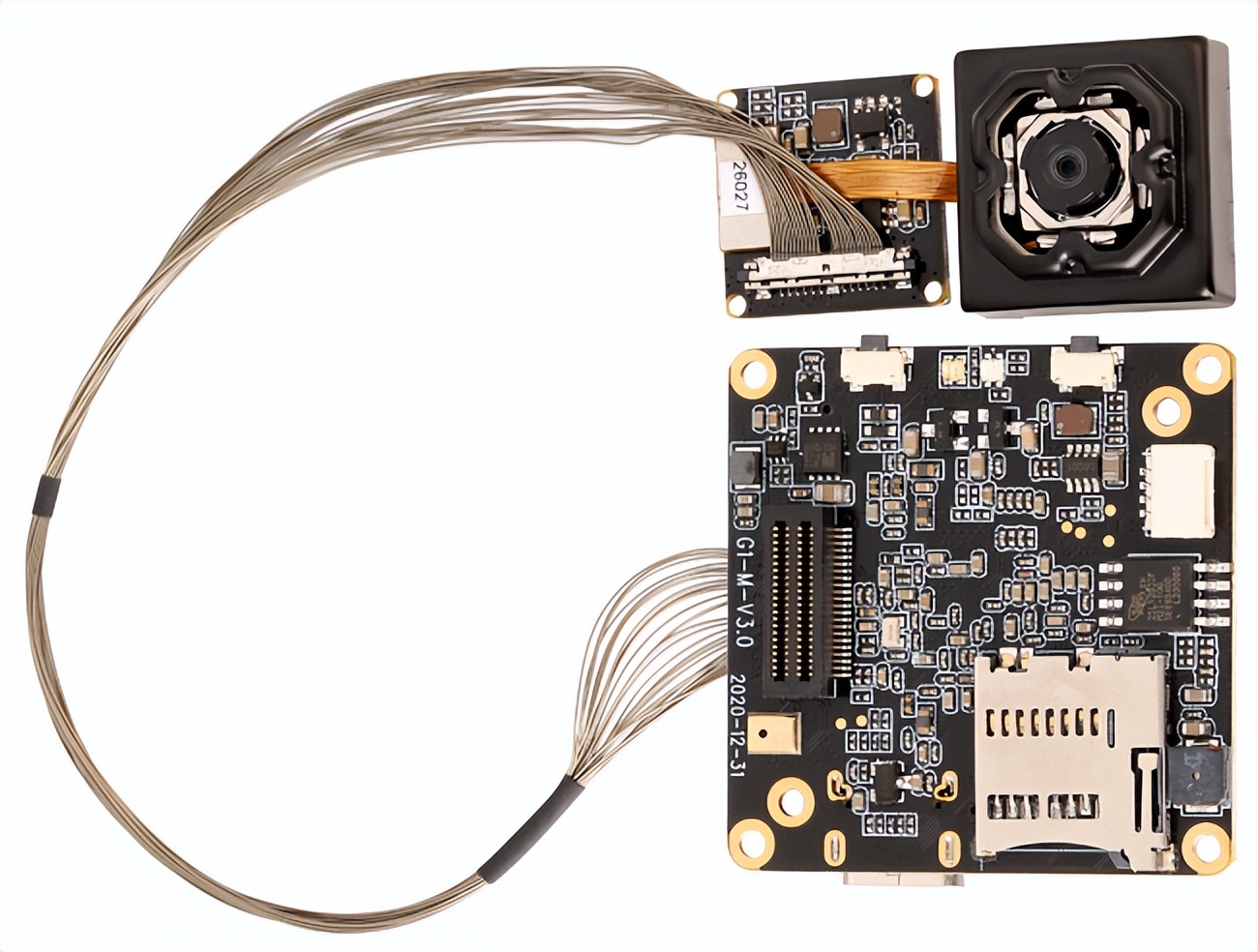

In the field of intelligent manufacturing, industrial robots are no longer just the traditional "mechanical arms." Today's robots integrate perception, analysis, and decision-making, and can perform high-precision operations in complex environments. One of the crucial components among them is the high-speed vision system—it is equivalent to the "eyes" of the robot, responsible for capturing environmental information and guiding the execution of actions. To ensure the stable and efficient operation of the vision system, the selection of cables has become an indispensable basic link.

Why are harnesses so crucial?

In high-speed visual systems, cameras need to transmit the massive image data collected with extremely short delays to the processing unit. If the cable performance does not meet the standards, it may lead to various problems:

Signal delay: leads to the mismatch between the image and the control system, affecting the robot's reaction speed.

Data loss: causing incomplete identification information and even operation misjudgment.

Insufficient anti-interference ability: External electromagnetic noise may cause distortion or fluctuation in the image.

In high-precision industrial manufacturing, these subtle signal anomalies will be amplified, directly affecting production efficiency and product yield. Therefore, the cable is not only a transmission medium but also a "hidden guarantee" for the stability of the visual system performance. Unique advantages of micro coaxial cable

Unique advantages of micro coaxial cable

Among the many types of cables, the extremely fine coaxial cable (micro coaxial cable) has become the preferred solution for industrial robot vision systems due to its high speed, flexibility, and high reliability:

High-speed transmission performance excellence: supports high-frequency, high-bandwidth signal transmission, ensuring real-time and complete transmission of image data to the processing unit.

Lightweight and high flexibility design: extremely small wire diameter, light weight, can be freely bent in multi-joint motion structures without affecting the accuracy of robot movements.

Excellent anti-interference ability: Its coaxial shielding structure effectively suppresses electromagnetic interference (EMI), maintaining clear signals even in environments with dense motors and inverters.

High durability and reliability: Excellent bending life and mechanical strength, capable of long-term stable operation under high-frequency movement.

Typical application scenarios

In the case of high-speed sorting robots, the visual system must complete object recognition and coordinate positioning within milliseconds. If there is any delay in the bundle transmission or signal interference, it may cause recognition errors and affect production efficiency.

As for precision assembly robots, their visual positioning accuracy requirements are extremely high. Once the image signal is distorted or there is transmission delay, it will lead to assembly errors and increase the不良率 of the product. It can be seen that the quality of the wire harness directly determines the operation stability of the entire visual system.

High-speed vision systems not only rely on algorithm optimization and hardware performance improvement, but also cannot do without the support of high-quality cables. Micro coaxial cable, with its advantages of high-speed transmission, flexible wiring, anti-interference, and high durability, has become an indispensable key component in the fields of intelligent manufacturing and industrial robots.

I amSuzhou Huichengyuan Electronic Technology, focusing on the research and development and customization of high-speed signal cable harnesses and ultra-fine coaxial cable harnesses, committed to providing customers with high-reliability and high-performance interconnection solutions. If you have related needs or want to learn more, please contact:Manager Zhang 18913228573 (WeChat number same).